Basic info:

High speed: 12000 sheets/hours

Accurate registration levels: ± 1mm

Sheet sizes: 400 mm -1650 mm

Top sheets thickness: 120 -500 g/m2

Bottom sheet thickness: above 300g/m2

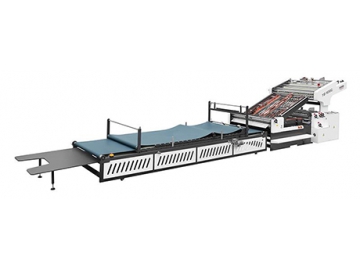

The sheet to sheet litho laminator is suitable for the laminating of cardboard and corrugated paper, and is suitable for the laminating of board-to-board products. The max speed of this machine is 12000sheet/hour. The upper paper feeding unit of this sheet to sheet laminating(mounting) machineadopts a position correcting device. The deviation can be corrected by the position correcting device when the paper stacking error is about 15mm, which greatly shortens the stacking time and solves the problem of the upper paper positioning accuracy between the left and right at a high speed.

The machine can automatically adjust the parts of the paper machine by setting the length and width of the paper on the touch screen. When replacing another type of paper, it takes only about 20 seconds to switch to new order.

| Max sheet size | 1450×1450mm |

| Min sheet size | 400×400mm |

| Top sheet thickness | 120-500g |

| Precision for front and back | ±1mm |

| Air Consumption | 0.2m3/min |

| Overall | 15.5×2.4×2.4M |

| Machine power | 22KW |

| Bottom sheet | A, B, C, E, F Corrugated paper Four Layers Corrugated paper: AB/BB/BC/EE Cardboard paper is above the 300GSM |

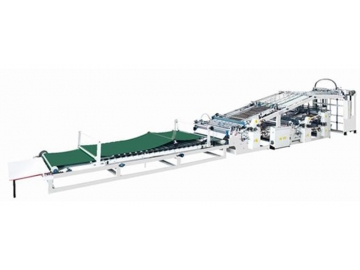

| Max sheet size | 1650×1650mm |

| Min sheet size | 400×400mm |

| Top sheet thickness | 120-500g |

| Precision for front and back | ±1mm |

| Air Consumption | 0.2m3/min |

| Overall | 15.7×2.6×2.4M |

| Machine power | 25KW |

| Bottom sheet | A、B、C、E、F Corrugated paper Four Layers Corrugated paper: AB/BB/BC/EE Cardboard paper is above the 300GSM |

(The parameters of the servo sheet to sheet laminating(mounting) machinecan be changed according to the actual needs of the customers.)

- Feeding unit: Regardless of thick paper or thin paper, the feeding unit ensures the high speed and smoothness of paper feeding process. This unit improves the production efficiency of the sheet to sheet laminating(mounting) machineduring the operation process.

- Bottom sheetsystem: The bottom sheet system adopts suction to feed paper automatically. The bottom sheet system ensures that the corrugated paper and the cardboard can be smoothly discharged during the operation process.

- Positioning system: The positioning system utilizes multiple sets of photoelectric to sense the relative position of the bottom paper. During the working process of the laminating machine, the positioning system makes the upper paper and the bottom sheet fit accurately.

- Transmission system: The transmission system makes the paper conveying smooth and fast during the operation of the laminating machine. The machine operates with low noise to achieve a quiet production environment.

- Electrical system: The man-machine interface is combined with the PLC to display various information such as warnings and detection faults on the screen, so that the user can know the condition of the machine in time when operating the paper machine.

- Gluing system: The gluing system uses a stainless steel gluing roller. The gluing roller made of stainless steel extends the useful life of the machine, making it more durable.

- Pre-loading unit: Under the condition of not stopping the machine, the pre-loading unit stack up the next stack of upper paper to improve the efficiency.

- Lead edge feeder: The lead edge feeder can be selected to satisfy the customer’s needs to adapt the sheet to sheet laminating(mounting) machineto all kinds of large-size corrugated paper feeding.

- YB-1450H Sheet to sheet litho laminator in Mexico

- YB-1450H Sheet to sheet litho laminator in Korea

- YB-1450H Sheet to sheet litho laminator in Brasil