Oven & Cooler

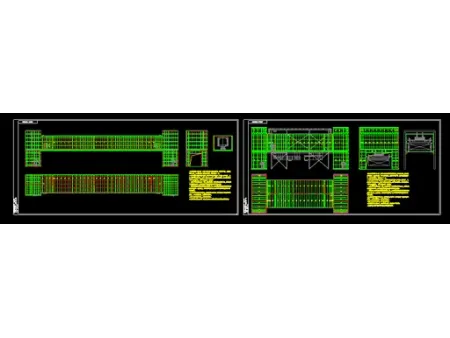

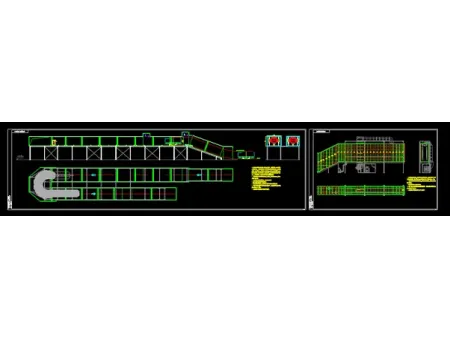

When determining the design and shape of the drying oven, we not only ensure it meets your production layout requirements but also consider several critical factors:

- Energy efficiency to reduce operating costs

- Minimizing temperature variations within the effective drying zone for consistent curing quality

- Space optimization to reduce the equipment footprint

- Efficient use of materials for cost savings and sustainability

- Ease of installation and transportation for smoother project execution

- Flexibility for future upgrades or expansions to adapt to evolving production needs

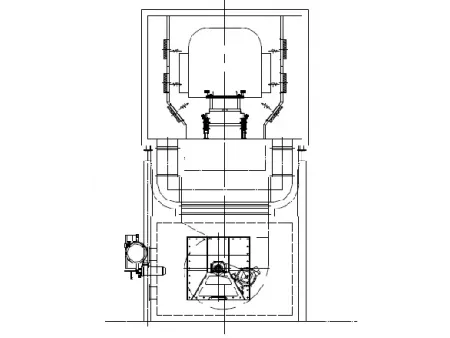

To best suit your available space and specific operational requirements, Tiancheng Coating offers drying systems in three layout configurations: π-Type Oven, Straight-Through Oven, and Bridge-Type Oven.

For paint shop exhaust, where VOC concentrations are typically low, the zeolite rotor concentration system is employed to efficiently capture 90–95% of VOCs. VOCs are adsorbed onto the zeolite rotor’s molecular sieve surface, and a small volume of desorption air is used to release the concentrated VOCs, significantly reducing the total air volume requiring further treatment while increasing VOC concentration for more effective downstream processing.

- High-volume exhaust air first passes through pre-treatment systems that remove paint mist.

- The cleaned air is directed toward the zeolite rotor, where 90–95% of VOCs are adsorbed.

- Purified air is discharged safely through a chimney, complying with emission standards.

- The concentrated VOC stream is then fed into the RTO (Regenerative Thermal Oxidizer) for complete combustion and safe disposal.

The regenerative thermal oxidizer (RTO) heats exhaust gases from spray booths or drying ovens to high oxidation temperatures, breaking down VOCs into harmless CO₂ and H₂O.

Main components include:- Applications: Odorous gases, organic exhaust emissions, and paint shop VOCs.

- Capacity Range: 5,000 – 180,000 Nm³/h.

- Treatment Efficiency: Up to 99.99% in three-chamber designs and 96% in two-chamber designs.

This system ensures effective VOC removal while maintaining energy efficiency and compliance with stringent environmental regulations.