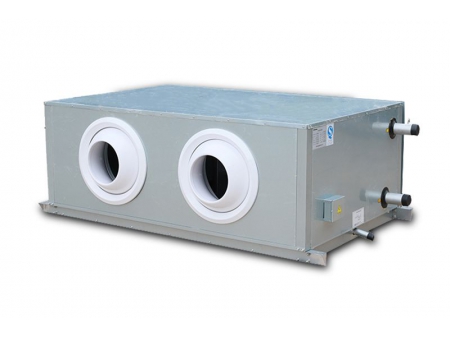

Ceiling Type Air Handling Unit

Request a Quote

Ceiling mounted air cooling units are used for ventilation and refrigeration in a number of buildings, ranging from industrial factories to shopping malls.

Download

Technical Parameters

| Model RFPD/4H | Air Flow (m³/h) | Rated cooling cap. (KW) | Rated heating cap. (KW) | Water Flow (m³/h) | Water D.P. (kpa) | ESP (pa) | Motor power (KW) | Dimension | Weight (KG) | Noise dB(A) | Water pipe (DN) | Drain pipe (DN) | ||

| L | W | H | ||||||||||||

010 | 1000 | 5.1 | 10.2 | 0.88 | 4.2 | 60 | 0.25 | 850 | 600 | 520 | 56 | 57 | 32 | 25 |

015 | 1500 | 8.4 | 15.2 | 1.44 | 9 | 60 | 0.25 | 950 | 650 | 570 | 63 | 57 | 40 | 25 |

020 | 2000 | 11.7 | 21.4 | 2.01 | 10.8 | 60 | 0.25 | 1100 | 750 | 570 | 81 | 58 | 40 | 25 |

025 | 2500 | 14.7 | 25.4 | 2.53 | 17.6 | 90 | 0.37 | 1100 | 850 | 570 | 83 | 59 | 40 | 25 |

030 | 3000 | 17.9 | 31.5 | 3.08 | 32 | 150 | 0.55 | 1100 | 1000 | 570 | 102 | 60 | 40 | 25 |

040 | 4000 | 23.6 | 41.1 | 4.06 | 60 | 180 | 0.75 | 1100 | 1280 | 620 | 106 | 60 | 40 | 25 |

050 | 5000 | 28.6 | 51.3 | 4.92 | 40 | 200 | 0.45x2 | 1100 | 1500 | 620 | 132 | 61 | 40 | 25 |

060 | 6000 | 35 | 62 | 6.02 | 42 | 200 | 0.55X2 | 1100 | 1630 | 620 | 152 | 62 | 50 | 25 |

070 | 7000 | 41 | 71 | 7.05 | 56 | 250 | 0.75x2 | 1100 | 1730 | 680 | 210 | 63 | 50 | 25 |

080 | 8000 | 45.5 | 84.3 | 7.83 | 32 | 250 | 0.75X2 | 1100 | 1730 | 740 | 251 | 63 | 50 | 25 |

090 | 9000 | 53 | 92.5 | 9.12 | 36 | 250 | 0.75x2 | 1100 | 1830 | 740 | 282 | 65 | 50 | 25 |

105 | 10500 | 62.1 | 110 | 10.68 | 48 | 280 | 1.1x2 | 1200 | 2130 | 740 | 302 | 67 | 50 | 25 |

120 | 12000 | 71 | 133 | 12.21 | 62 | 280 | 1.1x2 | 1200 | 2130 | 840 | 307 | 67 | 50 | 25 |

135 | 13500 | 77 | 148 | 13.24 | 25.4 | 320 | 1.8x2 | 1200 | 2130 | 900 | 375 | 69 | 65 | 25 |

150 | 15000 | 86.5 | 153.5 | 14.88 | 26.4 | 320 | 2.2x2 | 1200 | 2130 | 970 | 386 | 70 | 65 | 25 |

| NOTE: 1. Cooling conditions: inlet air DB27°C,WB19.5°C, inlet water temperature 7°C/12°C. 2. Heating conditions: inlet air DB21°C, inlet water temperature 60°C/50°C. | ||||||||||||||

| Model RFPD/6H | Air Flow (m³/h) | Rated cooling cap. (KW) | Rated heating cap. (KW) | Water Flow (m³/h) | Water D.P. (kpa) | ESP (pa) | Motor power (KW) | Dimension | Weight (KG) | Noise dB(A) | Water pipe (DN) | Drain pipe (DN) | ||

| L | W | H | ||||||||||||

010 | 1000 | 7.5 | 12.9 | 1.29 | 9 | 60 | 0.25 | 850 | 600 | 520 | 56 | 57 | 32 | 25 |

015 | 1500 | 113 | 20.6 | 1.94 | 18.6 | 60 | 0.25 | 950 | 650 | 570 | 63 | 57 | 40 | 25 |

020 | 2000 | 15.1 | 26.7 | 2.6 | 26.3 | 60 | 0.25 | 1100 | 750 | 570 | 81 | 58 | 40 | 25 |

025 | 2500 | 18.6 | 31.6 | 3.2 | 37.6 | 90 | 0.37 | 1100 | 850 | 570 | 83 | 59 | 40 | 25 |

030 | 3000 | 22.3 | 38.5 | 3.84 | 25 | 150 | 0.55 | 1100 | 1000 | 570 | 102 | 60 | 40 | 25 |

040 | 4000 | 31.1 | 50.2 | 5.35 | 49.1 | 180 | 0.75 | 1100 | 1280 | 620 | 106 | 60 | 50 | 25 |

050 | 5000 | 36.2 | 62.3 | 6.23 | 32.6 | 200 | 0.55x2 | 1100 | 1500 | 620 | 132 | 61 | 50 | 25 |

060 | 6000 | 44.6 | 74 | 7.67 | 45.1 | 200 | 0.55x2 | 1100 | 1630 | 620 | 152 | 62 | 50 | 25 |

070 | 7000 | 50.4 | 85 | 8.67 | 60.3 | 250 | 0.75x2 | 1100 | 1730 | 680 | 210 | 63 | 50 | 25 |

080 | 8000 | 58.9 | 99.2 | 10.13 | 55.6 | 250 | 0.75x2 | 1100 | 1730 | 740 | 251 | 63 | 50 | 25 |

090 | 9000 | 65.3 | 112.6 | 11.23 | 24.5 | 250 | 1.1x2 | 1100 | 1830 | 740 | 282 | 65 | 50 | 25 |

105 | 10500 | 75.8 | 137.1 | 13.04 | 22 | 280 | 1.1X2 | 1200 | 2130 | 740 | 302 | 67 | 65 | 25 |

120 | 12000 | 86.8 | 162 | 14.93 | 24 | 280 | 1.5x2 | 1200 | 2130 | 840 | 307 | 67 | 65 | 25 |

135 | 13500 | 103.4 | 175.8 | 17.78 | 60 | 320 | 2.2x2 | 1200 | 2130 | 900 | 375 | 69 | 65 | 25 |

150 | 15000 | 109.1 | 186.2 | 18.77 | 62 | 320 | 2.2x2 | 1200 | 2130 | 970 | 386 | 70 | 65 | 25 |

| NOTE: 1. Cooling conditions: inlet air DB27°C,WB19.5°C, inlet water temperature 7°C/12°C. 2. Heating conditions: inlet air DB21°C, inlet water temperature 60°C/50°C. | ||||||||||||||

| Model RFPD/6H | Air Flow (m³/h) | Rated cooling cap. (KW) | Rated heating cap. (KW) | Water Flow (m³/h) | Water D.P. (kpa) | ESP (pa) | Motor power (KW) | Dimension | Weight (KG) | Noise dB(A) | Water pipe (DN) | Drain pipe (DN) | ||

| L | W | H | ||||||||||||

010 | 1000 | 7.5 | 12.9 | 1.29 | 9 | 60 | 0.25 | 850 | 600 | 520 | 56 | 57 | 32 | 25 |

015 | 1500 | 113 | 20.6 | 1.94 | 18.6 | 60 | 0.25 | 950 | 650 | 570 | 63 | 57 | 40 | 25 |

020 | 2000 | 15.1 | 26.7 | 2.6 | 26.3 | 60 | 0.25 | 1100 | 750 | 570 | 81 | 58 | 40 | 25 |

025 | 2500 | 18.6 | 31.6 | 3.2 | 37.6 | 90 | 0.37 | 1100 | 850 | 570 | 83 | 59 | 40 | 25 |

030 | 3000 | 22.3 | 38.5 | 3.84 | 25 | 150 | 0.55 | 1100 | 1000 | 570 | 102 | 60 | 40 | 25 |

040 | 4000 | 31.1 | 50.2 | 5.35 | 49.1 | 180 | 0.75 | 1100 | 1280 | 620 | 106 | 60 | 50 | 25 |

050 | 5000 | 36.2 | 62.3 | 6.23 | 32.6 | 200 | 0.55x2 | 1100 | 1500 | 620 | 132 | 61 | 50 | 25 |

060 | 6000 | 44.6 | 74 | 7.67 | 45.1 | 200 | 0.55x2 | 1100 | 1630 | 620 | 152 | 62 | 50 | 25 |

070 | 7000 | 50.4 | 85 | 8.67 | 60.3 | 250 | 0.75x2 | 1100 | 1730 | 680 | 210 | 63 | 50 | 25 |

080 | 8000 | 58.9 | 99.2 | 10.13 | 55.6 | 250 | 0.75x2 | 1100 | 1730 | 740 | 251 | 63 | 50 | 25 |

090 | 9000 | 65.3 | 112.6 | 11.23 | 24.5 | 250 | 1.1x2 | 1100 | 1830 | 740 | 282 | 65 | 50 | 25 |

105 | 10500 | 75.8 | 137.1 | 13.04 | 22 | 280 | 1.1X2 | 1200 | 2130 | 740 | 302 | 67 | 65 | 25 |

120 | 12000 | 86.8 | 162 | 14.93 | 24 | 280 | 1.5x2 | 1200 | 2130 | 840 | 307 | 67 | 65 | 25 |

135 | 13500 | 103.4 | 175.8 | 17.78 | 60 | 320 | 2.2x2 | 1200 | 2130 | 900 | 375 | 69 | 65 | 25 |

150 | 15000 | 109.1 | 186.2 | 18.77 | 62 | 320 | 2.2x2 | 1200 | 2130 | 970 | 386 | 70 | 65 | 25 |

| NOTE: 1. Cooling conditions: inlet air DB27°C,WB19.5°C, inlet water temperature 7°C/12°C. 2. Heating conditions: inlet air DB21°C, inlet water temperature 60°C/50°C. | ||||||||||||||

Notes

- Fresh air working conditions: The air inflow dry bulb temperature is 7℃. Hot water inflow temperature is 60℃.

- Return air dry bulb temperature is 15℃. Hot water inflow temperature is 60℃.

Features

- Use of an aluminum alloy frame ensures a light weight, making it convenient for onsite dismounting and maintenance.

- Internal and external double layer polyurethane color steel panels avoids the formation of a cold bridge on the shell while operating.

- Units are operated and tested using dynamic and static equilibrium tests before delivery.

- Closed rolling bearings are used for the automatic adjusting center of gravity, automatic locking and push resistance. Pre-filling the lube oil ensures maintenance is not necessary during normal operating conditions.

- The filter is a plate type that can be cleaned and reused.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos