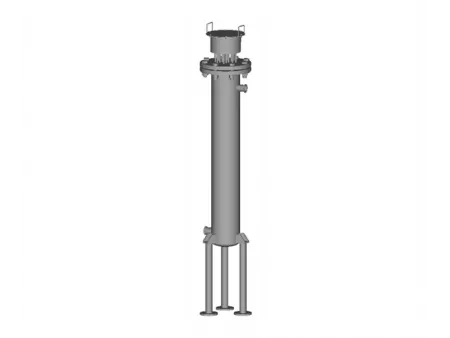

Tail Gas Inactivation System

Stainless Steel Tank & Vessel Manufacturing

Biological waste gas treatment system

In the production of biopharmaceuticals, the generation of waste gases containing potentially pathogenic bacteria and viruses poses significant hazards. These gases must undergo disinfection and sterilization treatment to eliminate the pathogens before being released into the atmosphere. Therefore, a waste gas treatment system is necessary for the inactivation treatment of these gases.

In response to this need, RITAI has developed a specialized electrically heated tail gas inactivation system. This biological waste gas treatment equipment is extensively utilized in handling exhaust emissions from biological fermentation, exhaust emissions during the sterilization of biochemical instruments in sterilization chambers, and exhaust emissions from biochemical wastewater treatment systems. The system has demonstrated significant efficacy in real-world applications.

RITAI's tail gas inactivation system is customizable in terms of size, materials, components, and other specifications. If you have related requirements, please do not hesitate to contact us.

- 100% sterile

- Automatic temperature control

- The tail gas inactivation system remains completely sealed throughout the process, free from contamination.

- Intelligent temperature control and alarm functions

- High temperature up to 300°C-800°C.

- Complies with the safety requirements for biological experiments.