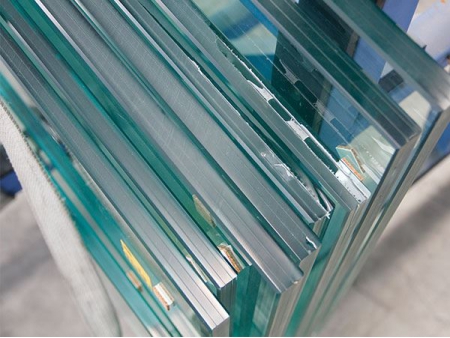

Multilayer Laminated Glass

PVB Color: clear, milky white, blue-green, French green, bronze, blue, grey, and etc.

Glass Color: clear, ultra clear, French green, dark green, bronze, dark blue etc.

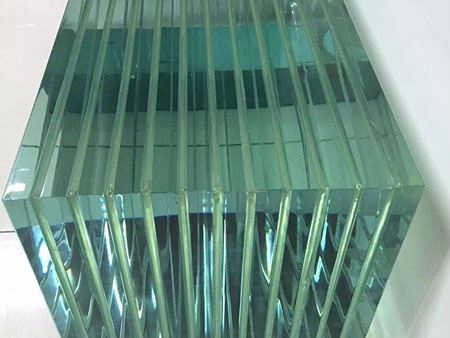

Glass Thickness: 8.76 mm, 10.38 mm, 10.76 mm, 12.76 mm, and etc., custom thickness acceptable

PVB Thickness: 0.38 mm, 0.76 mm, 1.14 mm, 1.52 mm, and etc.

Glass Size: custom size acceptable, up to 3300x12000 mm

Multilayer laminated glass is a popular choice for high-end building projects. It is made through a process called laminating, where multiple pieces of different types of glass are combined and bonded together with PVB films of varying thicknesses and colors. This results in a composite glass product that is both strong and aesthetically pleasing.

The glass used in multilayer laminated glass include clear float glass, ultra-clear glass, multi-colored online-coated glass, offline low-E glass, and more. This allows for a wide range of design options, including decorative color and lighting.

To create multilayer laminated glass, the glass and films undergo special high-temperature and high-pressure processing to permanently bond them together. This process can be done directly from raw glass or by cutting, edging, and tempering various types of glass before combining them.

- Improved safety performance

- Various color options

- UV ray blockage: the PVB film can absorb most of the ultraviolet rays in sunlight, protecting furniture and other items from aging.

- Light transmittance reduction: the PVB film can block the propagation of sound waves, making it effective as a soundproofing material.

- The strength and impact resistance make laminated glass suitable to be used in doors, windows, shower rooms, skylights for industrial buildings, shop windows, and other fragile architectures that store valuable items.

- Laminated glass is also frequently used in public facilities like schools, airports, hotels, and office buildings for accident-prone areas such as floor-to-ceiling windows, glass doors, and skylights.