Cup Gun Powder Coating System, COLO-800DT-C

The cup gun powder coating system is an excellent choice for powder coating test facilities, laboratories or custom shops. Well-balanced powder coating cup gun delivers consistent flow of powder. This test powder coating spray gun is suitable for small jobs but high quality users.

With a self-fluidizing application cup--150 ml

The powder cup is easy to clean without any tool, and it’s easy to change colors.

If you want to do large-scale coating, you only need to change a big hopper, but no need to change the gun or the machine unit, thus save the cost!

Features

1. This powder coating unit with a 1lb powder cup is ideal for laboratory use, sampling, testing and small batch production.

2. The mini powder cup is directly connected to the spray gun, which is easy to carry with compact structure.

3. Using multiple cups is more convenient for multi-color applications.

4. Intelligent controller supports to switch modes quickly during powder coating different objects.

5. Gives the economical, long lasting, and color-durable quality finishes available on virtually any type of metal.

Controller

- Precise adjustment of voltage from 0-100kV, and the voltage changes are clearly reflected in the LED screen.

- The air pump can be easily adjusted when conveying, atomizing and rinsing, making it suitable for powder coating different objects.

- 3 one-touch intelligent buttons stand for 3 pre-set application programs which are easily switched to adapt to different shapes of work parts:

Flat coating program for flat shape workpieces.

Corner coating program for complex shape parts or deep corners.

Recoating program for parts which have been coated again. - The air pump can be easily adjusted when , atomizing and rinsing, making it suitable for powder coating different objects.

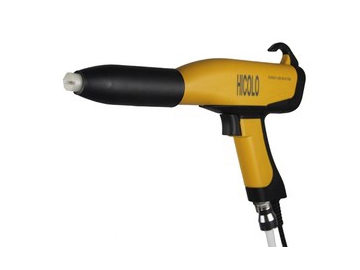

Spray Gun

- 100kv powder spray gun maximizes the electrostatic charging, offering the highest transfer efficiency.

- The ergonomic gun lies balanced in the hand, enabling to coat efficiently and quickly.

- Robust powder spray gun design decreases the failure rate and prolongs service life.

Spray Nozzles

- Full sizes of nozzle assortments are equipped to adapt to spraying various work parts, including round and flat nozzles, as well as nozzles with an extension for difficult areas.

- The use of high quality non-stick materials prevents powder accumulations and allows a high quality color change.

Powder Cup

- Size: D10*H10 cm; capacity: 1 lb

- This powder cup is self-fluidizing and easy to clean.

- Powder in this mini cup is completely fluidized without powder accumulation and absorbed moisture, ensuring a constant and even powder flow.

Parameters of the Cup Gun Coating Machine

Electrical Data

Power range: 220V/110V

Frequency: 50HZ

Temperature range in use: -10℃ 50℃

Spray Gun

Gun weight: 500G

Rated output voltage: 24VDC

Input voltage: -200kV

Maximum output current: 180uA (max.)

Maximum output voltage: 0-100KV (adjustable)

Maximum powder injection: 600g/min

Polarity: negative (-)

Pneumatic Data of the Cup Gun Powder Coating System, COLO-800DT-C

Maximum input-air pressure: 10kg/cm

Optimum input-air pressure: 6kg/cm

Minimum input-air pressure: 4kg/cm

Maximum water vapor content or compressed air: 1.4g/Nm3

Maximum oil vapor content of compressed air: 0.1ppm

Maximum compressed-air consumption: 13.2m3/h