Plated Thermostatic Concealed Shower Valve

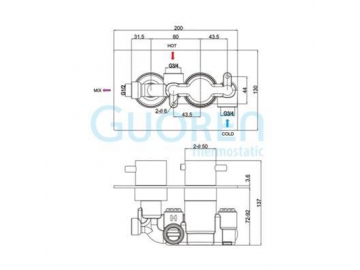

- AZ32A

AZ32A

AZ32A

Material

The main body of plated thermostatic concealed shower valve uses HPb59-1(grade A brass).

Zinc alloy made faucet handwheel is anti-oxidation and corrosion-resistant.

The HPb59-1 panel is anti-oxidation and corrosion-resistant.

The copper made thermostatic cartridge is able to inhabit the bacteria from growing with effect.

Operating conditions:

1. The optimum working pressure is 0.5-5Bar, we suggest a pressure-increasing valve be installed when the pressure is lower than 0.5Bar.

2.The outlet temperature of the cold water is 4℃-25℃and the hot water is 55℃-85℃.

3.The safety temperature is set at 38℃±2℃.

4.Anti-scald: When the cold water supply fails, during the first 5 seconds (±0.5 seconds) if the outlet water volume is less than 200ml, the outlet temperature is within 49℃, otherwise the temperature should be less than 42℃ and the volume be less than 300ml, and the temperature is less than 49℃ in the following 30seconds. Besides, the temperature difference between the outlet water and the set temperature should be within 2℃.

5. Stable outlet water temperature: when the inlet water temperature is constant and the inlet pressure is 0.3 MPa then either pressure of the cold or hot water reduces by 20%; or when the inlet pressure is 0.3 Mpa, the inlet temperature of hot water varies by 10%, eventually the outlet water temperature difference is found to be within 2 ℃ compared with the set temperature.

Available standards:

BS EN1111, BS EN1287, ASME A112.12.1/CSAB 125.1, ASSE 1016 and AS 4032.2

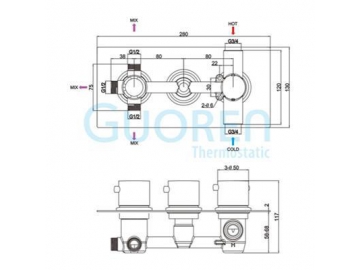

GR-AZ-32C

GR-AZ-32C  GR-AZ-32D

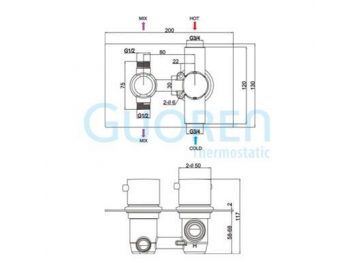

GR-AZ-32D  GR-AZ-32E

GR-AZ-32E