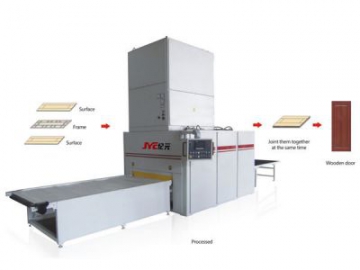

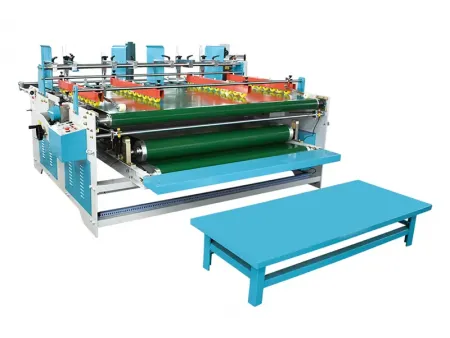

Radio Frequency Press / Slant Gluer for Door Frame Assembly

The radio frequency press is a special style of RF edge gluer for door frame assembly purpose. Due to its design of a slant working table, it is also called a slant gluer. Backed by our vast experience in RF press industry, the slant gluer is one of the most productive radio frequency presses in woodworking industries. This RF press can be used for solid wood door frame assembling, solid wood edge banding, door pocket edge banding, cabinet door assembling, panel jointing, etc.

Features of the Radio Frequency Press

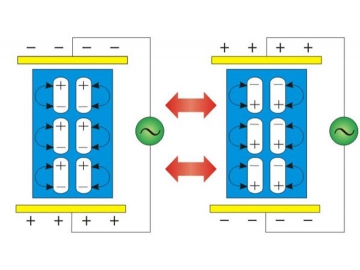

1. High Frequency Heating

The frame press applies high power radio frequency generator which can ensures fast heating, thus improving production efficiency. Whole working table heating only needs 2-3 minutes. For those woods with less glue, the heating time is about 1 minute. For example, HUAFENG Furniture Group uses our radio frequency press and spends only 1 minute and 30 seconds to heat furniture door panel.

2. Short Work Cycle

When using this door frame press, you can enjoy extremely short work cycle that is only 1-2 minutes.

3. PLC Control

PLC control system enables that the press can automatically complete various processes including adding pressure from positive and side direction, high frequency heating, pressure maintaining, pressure removing, etc. It also boasts fault self checking and alarm function.

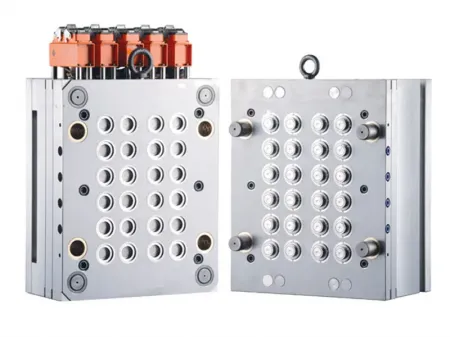

4. Hydraulic 3D Pressure

The door frame assembly press allows pressure at three directions. The hydraulic pressure cylinder at each direction can be ganged and controlled individually as well. Therefore, this radio frequency press can be used for wood board joining as well as frame assembling.

5. Slant Working Table

User friendly designed slant working table is convenient for operation and can alleviate labor strength.

6. Protective Devices

At both sides of this radio frequency press, optoelectronic switch protective devices are equipped for avoiding dangers caused by misoperation. In addition, the machine features multi protection from overheating, over current, spark, wind pressure, photoelectricity, ensuring safe operation.

Technical Parameters of the Radio Frequency Press

| Model | ||

| Working table | 1200×600mm | 1600×800mm |

| Control type | PLC Control | |

| Power supply | 3 phase 380V, 50Hz | |

| Output power | 15KW | |

| Frequency | 6.78MHz | |

| Pressure | Hydraulic 3D pressure | |

| Commutate mode | Three phase full wave silicon commutate | |

| Cooling mode | Forced Air Cooled | |

| Functions | 1) Small board joining | |

| 2) Solid wood frame jointing | ||

| 3) Door pocket edge banding | ||

| 4) Solid wood door assembling | ||

| 5) Solid wood edge banding | ||

| Model | ||

| Working table | 2460×960mm | 2460×1220mm |

| Control type | PLC Control | |

| Power supply | 3 phase 380V, 50Hz | |

| Output power | 20KW | |

| Frequency | 6.78MHz | |

| Pressure | Hydraulic 3D pressure | |

| Total pressure | 35T | |

| Commutate mode | Three phase full wave silicon commutate | |

| Cooling mode | Forced Air Cooled | |

| Functions | 1) Solid wood frame jointing | |

| 2) Solid wood edge banding | ||

| 3) Door pocket edge banding | ||

| 4) Solid wood door assembling | ||

| 5) Finger joint board joining | ||

| Model | |

| Working table | 3050×1220mm |

| Control type | PLC Control |

| Power supply | 3 phase 380V, 50Hz |

| Output power | 20KW |

| Frequency | 6.78MHz |

| Pressure | Hydraulic 3D pressure |

| Total pressure | 35T |

| Commutate mode | Three phase full wave silicon commutate |

| Cooling mode | Forced Air Cooled |

| Functions | 1) Solid wood frame jointing |

| 2) Batten sealing | |

| 3) Door pocket edge banding | |

| 4) Solid wood door assembling | |

| 5) Finger joint board joining |

Application

- Door assembly with glass inside

- Door edge banding

- Solid wood door making