Sheet to Sheet Mounter/Laminator with Stacker

Request a Quote

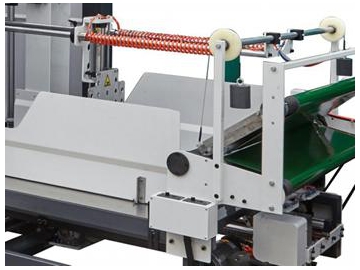

The Automatic sheet to sheet laminating(mounting) machineand flip flop machine is specially designed for the combining of color printing paper and corrugated paper. The automatic flipping stacking function completely replaces the manual operation of this task. This type of machine can receive paper and achieve positive and negative paper stacking automatically, which is completely labor and cost-saving.

We produce three different types of sheet to sheet laminating(mounting) machinefor you to choose from.

YB-1300ES Automatic sheet to sheet laminating(mounting) machineand flip flop machine

| Max sheet size | 1300×1250mm |

| Min sheet size | 500x500mm |

| Top sheet thickness | 150-600g |

| Bottom sheet thickness | A/C/C/E/F Corrugated paper, four ply corrugated paper |

| Fitting precision | ±1mm |

| Measurement | 20x2.6x3M |

| Machine power | 16KW |

YB-1450ES Automatic sheet to sheet laminating(mounting) machineand flip flop machine

| Max sheet size | 1450×1250mm |

| Min sheet size | 500x500mm |

| Top sheet thickness | 150-600g |

| Bottom sheet thickness | A/C/C/E/F Corrugated paper, four ply corrugated paper |

| Fitting precision | ±1mm |

| Measurement | 20x2.6x3M |

| Machine power | 17KW |

YB-1650ES Automatic sheet to sheet laminating(mounting) machineand flip flop machine

| Max sheet size | 1650×1450mm |

| Min sheet size | 500x500mm |

| Top sheet thickness | 150-600g |

| Bottom sheet thickness | A/C/C/E/F Corrugated paper, four ply corrugated paper |

| Fitting precision | ±1mm |

| Measurement | 21x2.8x3M |

| Machine power | 18KW |

(The parameters of the automatic sheet to sheet laminating(mounting) machineand flip flop machine can be changed according to the actual needs of the customers.)

Features

- The upper paper and the bottom sheet adopt automatic tracking and positioning technology to make the alignment of the upper paper and the bottom sheet more precise.

- When the paper is stacked to a certain height, the collection tray will automatically descend and slide out along the track, and the secondary plate will rise to achieve non-stop delivery of paper.

- The machine automatically stacks the papers in a positive and negative stacking manner, and automatically stacks the stacked sheets to achieve automatic paper delivery.

Components

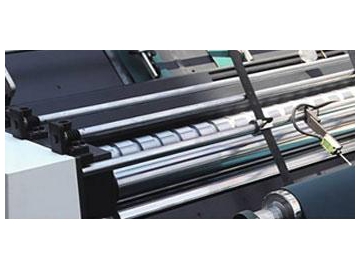

- Feeding unit: The feeding unit enables the smoothness of paper feeding process and can feed different types of upper paper

- Side-pull gauge positioning system (Optional) : The side-pull gauge positioning system is used to correct the left and right errors of the upper paper during the stacking and conveying process, so that the upper paper is positioned accurately.

- Electrical system: The main electrical components are from well-known brands, such as Schneider, Siemens, etc. Equipped with PLC tracking technology and automatic fault detection device, so that the operator can easily operate the machine.

- Pressure regulation system: The pressure regulation system adopts single-side pressure adjustment to ensure that the pressure on the left and right sides of the paper is consistent, so that the machine can adjust the specifications of the bottom sheet in one step when changing the paper specifications.

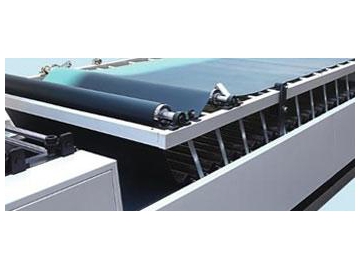

- Transmission system: Adopt pressing conveyor design, no need to adjust the pressure. In addition, the elevated delivery table makes easier for workers to collect papers.

- Pre-loading unit: Under the condition of not stopping the machine, the pre-loading unit stack up the next stack of upper paper to improve the efficiency.

- Flip flop system: Stack the fitted papers in a positive and negative stacking manner according to the set quantity.

Product package

Our automatic sheet to sheet laminating(mounting) machineand flip flop machine is sold in Italy and other countries around the world. You can click on the picture below to learn more about it.

YB-1450ES Automatic sheet to sheet laminating(mounting) machineand flip flop machine IN ITALY

YB-1450ES Automatic sheet to sheet laminating(mounting) machineand flip flop machine IN ITALY

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos