Pre-insulated Piping System for Heating

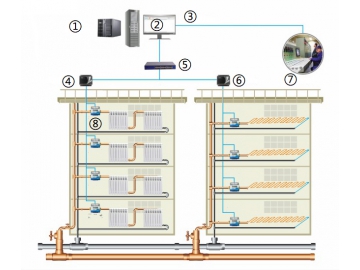

The pre-insulated piping systems for heating we engineer at WANLI PIPELINE are designed to distribute chilled water, hot water, heat transfer oil and other fluid mediums, which can be widely used in petrochemical, manufacturing industry, municipal works and other fields. The piping system has a wide range of applications, strong practical performance, no compensation laying design and advanced manufacturing technology, making the product more competitive.The piping system conforms to GB/T 29047-2012 China’s national standard, EN253/ASTM standards.

| Distribution mediums | Hot water, chilled water, returning water of air conditionings etc. | Designed pressure | ≤1.6MPa |

| Service life | 30 years | Designed temperature | ≤140℃ |

| Used spot | Underground where is no impact to vehicles, pedestrians passing by and vegetation, is also can be used indoors and outdoors above ground laying. | ||

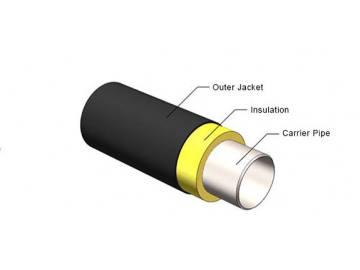

The pre-insulated piping system for heating we engineer at WANLI PIPELINE is composed of a steel, cooper, stainless steel or PPR carrier pipe, cell closed polyurethane foam insulation, and a heavy-weight, seamless, high density polyethylene outer jacket. The outer jacket can also be PVC, HDPE or metallic pipes.

- Prefabricated piping and fittings ensure more stable product quality and greatly reduce the time of field installation, thus significantly shortening the construction period.

- Uncompensated laying technology: avoids the possible accessories loss caused by using compensators and helps to reduce investment cost for you.

- Cell closed polyurethane foam insulation, offering the lowest available thermal insulation and the best natural resistance to water penetration.

- WANLI PIPELINE provides diversified above ground piping system solutions for different application conditions.

WANLI PIPELINE is an expert of manufacturing pre-insulated pipeline, be able to provide you a complete set of piping systems and fittings to your engineering demands.

-

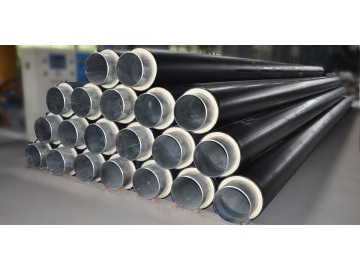

- Straight pipe

-

- Elbow pipe

-

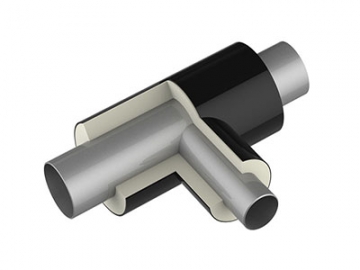

- Pipe Tee

| DN[mm] | Carrier pipe Dy×s[mm] | Insulation thickness[mm] | Outer jacket Dy×s[mm] | Delivered length [m] |

| 50 | 57*3.5 | 33.5 | 133*4.5 | 6 |

| 65 | 76*4 | 37 | 159*4.5 | 6 |

| 80 | 89*4 | 30.5 | 159*4.5 | 12 |

| 100 | 108*4 | 49.5 | 219*6 | 12 |

| 120 | 133*4.5 | 37 | 219*6 | 12 |

| 150 | 159*4.5 | 51 | 273*6 | 12 |

| 205 | 219*6 | 47 | 325*6 | 12 |

| 255 | 273*7 | 45 | 377*7 | 12 |

| 300 | 325*8 | 42.5 | 426*8 | 12 |

| 350 | 377*8 | 42.5 | 478*8 | 12 |

| 400 | 426*8 | 43.5 | 529*8 | 12 |

| 450 | 478*10 | 43 | 580*8 | 12 |

| 500 | 529*10 | 42.5 | 630*8 | 12 |

| 600 | 630*10 | 37 | 720*8 | 12 |

| 700 | 720*10 | 42 | 820*8 | 12 |

Note: above parameters are theorectical value and the subject to actual samples. All products can be customized to customer demands.