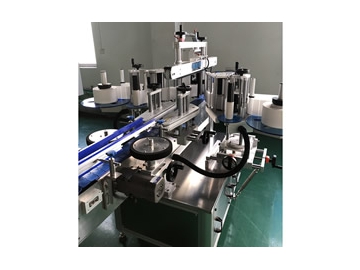

Twin Labeling Machine

Applications of Twin Labeling Machine JND-650

J&D twin labeling machine can stick labels on two sides at the same time. It is applicable for various cylindrical bottled or canned products like beverage and wine, chemicals, petroleum, mechanical oil and washing-up liquid, etc.

Features of Twin Labeling Machine JND-650

1. ss304 and anodically treated aluminum alloy are adopted to make the machine body.

2. Stepper motor imported from Japan is adopted to drive the labeling head.

3. Photoelectric photocells, which are imported from Japan or Germany, are available in this labelling machine to guarantee a precise labeling.

4. PLC control system, human-machine interface and sixty-suite memory unit are all available.

5. The labeling machine will auto stop working when there is problem for bottle feeding.

6. More functions: bottle position correction, bottle management, counter, and label ironing are all available.

7. Adjustable label height, position and angel, etc.

8. For the labeling of different containers with close size, there is no need to exchange spare parts for our powerful correction device.

9. Conveyor could be installed when used in production lines.

Note: (You can find a package production line in J&D composed of: bottle filling machinery, bottle labelling machines, ink jet printer and shrinkable packaging equipment, etc., which is especially suitable for beverage and milk production companies.)

| Model | JND-650 | JND-650H |

| Label Size | width 10-130mm (no length limit) | width 10-200mm |

| Labelling Accuracy | ±1 mm | |

| Speed | 0-25m/min (adjustable) | |

| Power | 600W AC110V/220V 50/60HZ | |

| Container Thickness | 25-135mm (customizable) | |

| Container Height | 40-320mm (customizable) | |

| Total Weight (kg) | 330 | |

| Dimension (L×W×H) (mm) | 2500×1400×1550 | |

| Package size(L×W×H) | 2800×1650×1800 | |