Vacuum Furnace Control System

Vacuum Control

Intelligent control system integrated to vacuum heat treatment furnaces

Our intelligent control system is designed for centralized monitoring, remote control, data analysis, and optimization management of vacuum heat treatment equipment. This advanced system enhances production efficiency, process accuracy, and equipment utilization across various industrial applications.

- Process management

Automatically selects heat treatment process parameters based on material and production information. - Process tracking

Records real-time heat treatment process data, including equipment status and workpiece processing conditions. - Historical trend data

Captures real-time data such as temperature, vacuum level, and water pressure in milliseconds, supporting trend analysis and report export for up to 10 years. - Quality defect reporting (QDR)

Generates QDRs based on material information and actual device data to evaluate processing quality. - Offline system maintenance

Supports offline updates and upgrades for system optimization.

- Full PCS integration

Incorporates all functionalities of PCS for comprehensive control. - Process workflow management

Facilitates process creation, review, execution, and management for seamless workflow control. - Intelligent scheduling

Offers priority-based scheduling based on equipment status and material conditions, enhancing equipment utilization and operational efficiency. - Smart dashboard

Displays real-time dynamic charts for equipment status, workpiece processing, and energy consumption, supporting both PC and mobile device synchronization. - Mobile operation console

Enables synchronized mobile control, allowing main functions to be operated via mobile devices. - Universal data communication bus

Compatible with mainstream communication protocols, ensuring seamless integration with existing systems for uninterrupted data communication. - Data analysis and fault prediction

Utilizes big data and AI algorithms to analyze historical data, predict equipment faults, and optimize heat treatment control processes, thereby enhancing efficiency and reducing downtime.

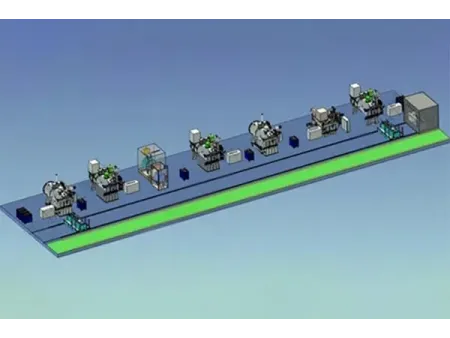

We provide control system upgrades for vacuum heat treatment lines and equipment, ensuring full compatibility with existing treatmeny methods and operational workflows. The upgraded system integrates an intelligent process expert system, significantly enhancing control precision, workpiece processing quality, and overall working stability.

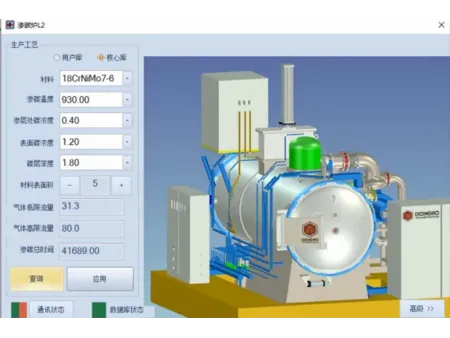

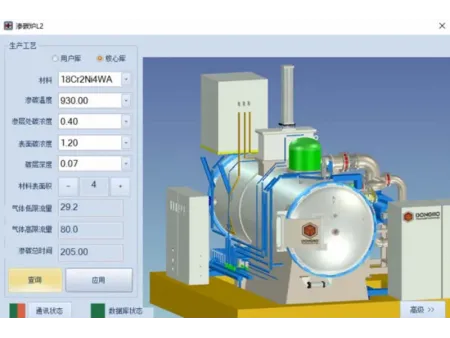

- 18CrNiMo7-6 1.8mm carburizing process18Cr2Ni4W 0.07mm carburizing process

- 18CrNiMo7-6 1.8mm carburizing process18Cr2Ni4W 0.07mm carburizing process

- TC4 0.2mm carburizing process 20CrMoH 1.65mm carburizing process

- TC4 0.2mm carburizing process 20CrMoH 1.65mm carburizing process

To meet the technical requirements for workpiece surface area during furnace loading, the process expert system incorporates a dedicated surface area calculation method and specialized software. The supplier is responsible for modeling and calculating the surface area based on the batch specifications of the buyer’s products and will provide the corresponding calculation methods and related software. The surface area of components is calculated using finite element modeling (FEM) or commercial design software to ensure accuracy. Additionally, we have established a customized surface area database tailored to user requirements, allowing for efficient and timely selection of appropriate processing parameters.

The process expert system supports both standard mechanical surface area calculations and finite element modeling (FEM) calculations to ensure precise measurement of component surface areas. Based on these calculations, the system can automatically adjust the carburizing gas flow rate according to the surface area, ensuring uniform and efficient carburizing results.

The process expert system is designed to meet diverse carburizing requirements for different materials. It includes a comprehensive database covering most materials commonly used in China. If a material is not indexed in the database, the system can automatically adapt and add related materials based on their composition, ensuring flexibility and accuracy in process selection.