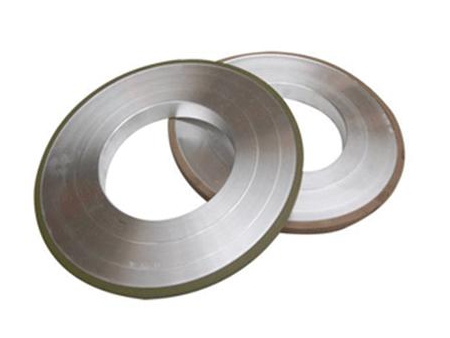

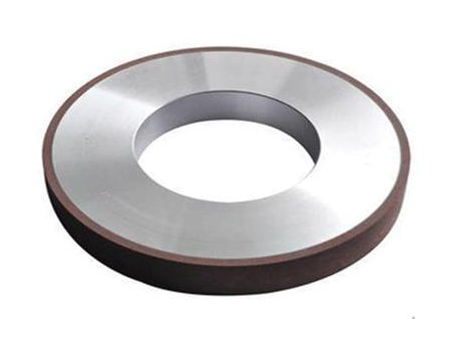

Diamond Grinding Wheel

Request a Quote

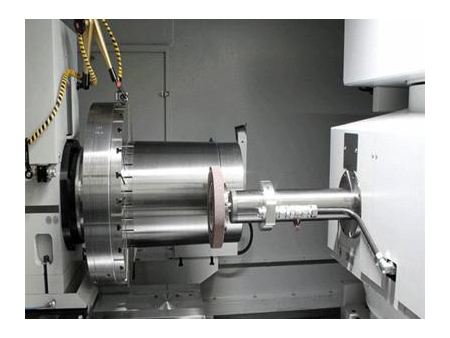

As a professional manufacturer of precision tools, LONNZ offers a wide array of abrasive grit, resin bond diamond grinding wheels and metal bond grinding wheels for precision grinding applications on the hardest materials.

Parameter

| Bond name | Bond Symbol | Applied range | ||

| Abrasive Grit | Application | |||

| Small range | Large range | |||

| Industrial diamonds | RVD | 60/70--325/400 | Resinoid bonded grinding wheels: used for carbide tool cutter sharpening or grinding | |

| MBD | 35/40--325/400 | 30/40--60/80 | Metal bond grinding wheels: used for rough grinding and sharpening of hard metal or the processing of glass and ceramics. | |

| SCD | 60/70--325/400 | Resinoid bonded grinding wheels, manufacturing steel, hard alloy components | ||

| SMD | 16/18--60/70 | 16/20--60/80 | Metal bond grinding wheels: used for saw cutting, drilling, trimming | |

| DMD | 16/18--60/70 | 16/20--40/50 | Metal bond grinding wheels: used for trimming cutter and other Single Grit tools | |

| M-SD | 36/54--0/0.5 | Used for fine grinding and polishing of hard metals, optical glass, ceramics, gemstones | ||

The main bonding agents used by our company are resinoid bonds and metallic bonds

| Bonding agent | Symbol | Feature | Use |

| Resinoid bond diamond grinding wheel | B | Advantages: excellent self-sharpening performance, difficult to block, produce less heat, easy to trim; Disadvantages: poor heat resistance, isn’t suitable for heavy duty grinding | semi-grinding and fine grinding of hard alloy, cutting tools and metalloid |

| Metallic bond diamond grinding wheel | Me | Advantages: strong bonding force, sharped cutting edge, high processing efficiency; Disadvantages: short service life due to the limitation of plating. | Semi-grinding, fine grinding and sharpening of glass and ferrite bead material. Because it is highly precise, it can also be used for manufacturing extra thin and special abrasives. |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos