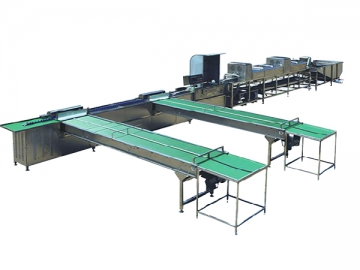

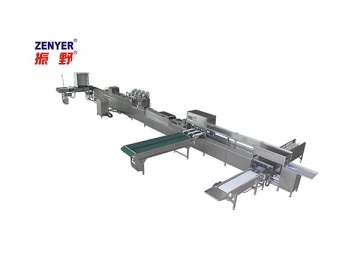

302B Egg Processing Line with Cleaning & Grading (10000 EGGS/HOUR)

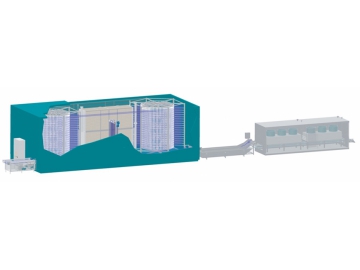

ZENYER 302B egg processing line is comprised of an egg washer and egg grader, and includes water bath single line loading, washing, drying and grading process with a maximum capacity of 10000 eggs/hour. This line is specially designed for duck egg processing, and the processing line ends up packing washed eggs manually for commercial purposes or turning the eggs into cooked duck egg products.

This processing line is completely PLC system controlled, equipped with an individual control panel for setting grading levels, calibrating accuracy, accumulate quantities and alarm and automatically diagnose any malfunctions.

| Product name | Egg Processing Line |

| Product code | 302B |

| Model | ZYL-YS1-D1-2P |

| Capacity | 10000 eggs/hour |

| Material | Stainless steel |

| Accuracy | ±1g |

| Power | 6 KW |

| Voltage | 380V,50HZ, three phase |

| Dimension(L×W×H) | 13.3 ×3×1.16 M |

| Net weight | 1200KG |

| Gross weight | 1500KG |

| Function | Water bath loading, Washing, drying, candling, grading and manual collecting or packing |

- Water bath loading

- Washing

- Drying

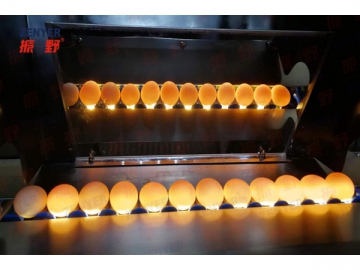

- Candling

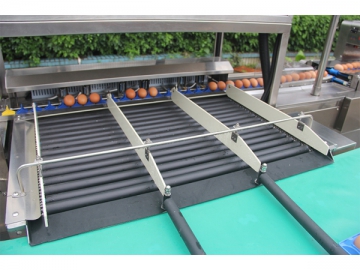

- Grading (electronic sensor weighing)

- Manual collection or packing

Pour an entire tray or box of eggs into the water bath, which will then carry the eggs to the washer entrance in a single line with the use of a conveyor. This loading method not only saves labor, but also minimizes egg cracking with the use of a buoyancy force. The eggs are also easier to wash after they have gone through a water bath.

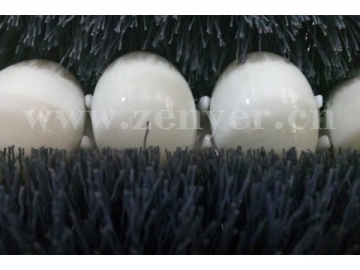

Eggs are fully cleaned using two brush sets and a warm water spray. Brush modules are flexible, and adjustments can be made to the brush distance, position, and speed.

Eggs are perfectly dried using a dry brush and strong air pressure.

Eggs will run through LED lights for a candling purpose, allowing users to easily remove any unqualified eggs, such as those that leak or have cracks.

The PLC system controlled electronic weighing system grades eggs based on weight with a maximum of 6 grade levels.

Processed eggs are manually packed or filled into trays.