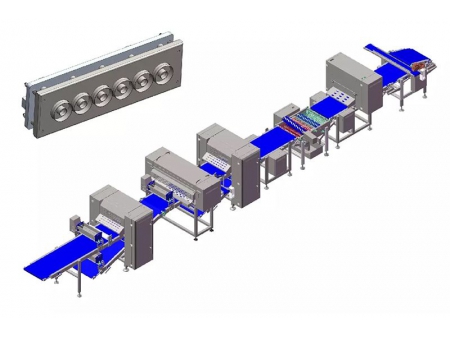

Donut/Berliner Line

Request a Quote

- Donuts

- Berliner

This bakery line is ideal for the automatic production of donuts and berliners. After dough mixing and fermentation, the prepared dough is placed on the infeed conveyor. It then passes through a sheeter, forming a continuous dough sheet. A rotary cutter accurately shapes the dough into donuts and berliners with ideal diameters and thicknesses.

The center dough is automatically removed by a hole picker, and dough trimmings are collected in containers for recycling. The formed donuts and berliners are then either automatically aligned into trays or transferred directly to the proofing system, followed by frying, glazing, coating, cooling, freezing, and packing.

Parameters

| Line model | ZLTTQ-650 |

| Line type | Straight line |

| Line size | L15.0m*W2m*H2.4m |

| Belt width | 650 mm |

| Dough width | 600 mm |

| Dough thickness | 5 mm-30 mm |

| Power/voltage | 17 kW/380 V,50 HZ, 3 PH (supplied as demand) |

| Product diameter | 80, 90 (or other sizes as per customer request) |

| Product weight | Depending on the product sizes |

| Production capacity | Max. 1000 kg/hr |

Features

- The donut and berliner line is equipped with video monitoring devices, allowing easier observation of equipment operation at all key stages.

- The bakery equipment features a remote control system for monitoring abnormal data and performing remote optimization.

- It includes an automatic thickness adjustment function, and multiple products can be switched with one click by saving recipes.

- The entire donut and berliner line is made of stainless steel and high-quality electrical components.