LJ300A Al Tube Line, Aluminum Tube Line

Continuous Extrusion Machine for Aluminum Tube

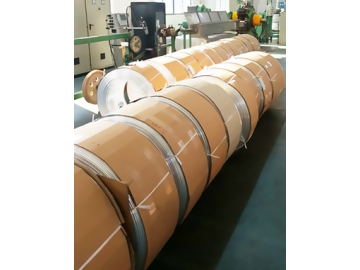

The LJ300A continuous rotary extrusion line adopts high cleanness aluminum rod as the feedstock to manufacture round aluminum tubes with the diameter from 4.5mm to 20mm, as well as square tubes with maximum width of 35mm. The feedstock is made into the aluminum tube at a stroke, without further processes such as annealing, surface treatment, etc.

Available with an online eddy current flaw detector, this series of continuous rotary extrusion line for aluminum tubes is able to guarantee the product quality. The extruded aluminum tubes are often used for refrigerator and freezer evaporators as well as the multi-channel pipeline system for automobile air conditioners and intercoolers.

| Main Unit: Continuous Rotary Extrusion Equipment | |

| Model | LJ300A |

| Nominal Diameter of Extrusion Wheel | 300 mm |

| Rated Rotation Speed | 20 RPM |

| Power of Main Motor | 110kW |

| Feedstock: Aluminum Rod | |

| Diameter | Φ9.5 mm -Φ12mm |

| Diameter Tolerance | ±0.2mm |

| Yield Strength | 90MPa |

| End Product: Aluminum Tubes | |

| Sectional Area Range | 8-120mm² (Ф6.5-Ф14 mm aluminum tube) |

| Max. Width | 35mm (square tubes) |

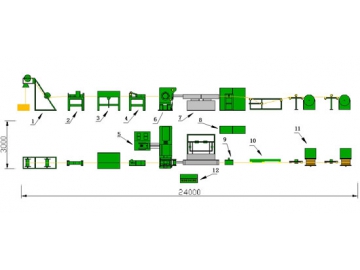

| Production Line: Aluminum Tube Production Line | |

| Average Output | 100 kg/h-160 kg/h |

| Installed Capacity | 380V, 3 phase, 150KVA |

| Flash Amount | ≤1% |

| Feedstock Pay-off Machine | one pcs |

| Aluminum Rod Straightening Machine | one pcs |

| Scrubbing Machine | one pcs |

| Ultrasonic Washing Unit | one pcs |

| Aluminum Rod Cutter | one pcs |

| Continuous Extrusion Machine | one pcs |

| Cooling System | one set |

| Meter Counter | one set |

| Sxy800 Take-up Machine | two sets |

| Electrical Control System (with Touch Screen) | one set |

| Hydraulic and Lubricating System | one set |

| Ultrahigh Pressure Hydraulic Station | one set |

Aluminum Extrusion Processing, Continuous Rotary Extrusion Process, Aluminum Extrusion Equipment Manufacturer