Custom Lightweight Metal Clips

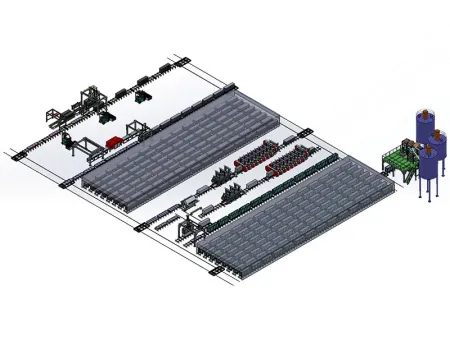

Mumeistory manufactures metal clips in a variety of materials, sizes and shapes to satisfy your exact requirements. Whatever your application, whatever your need, GEMCO has the manufacturing capabilities and expertise to make your part the way need it at an affordable cost. To guarantee the quality of finished products, we control it from the source, meaning we use only high quality low-carbon steel, stainless steel, copper, zinc alloy and other raw materials to produce metal clips. We will also supply the raw material test report upon request. Metal clips are processed using a precision CNC punching machine to ensure high consistency of finished products. The whole stamping process is highly automated, requiring less labor for control during the actual production. It not only saves cost, but improves production efficiency. This enables us to complete mass production in a short amount of time. If you want metal clips with a simple structure which requires only one-time stamping for forming, then we can produce over 100 thousand per day. For more complicated metal clips that are comprised of several parts, we will use automatic assembly equipment for the subsequent assembly, which saves both time and production costs.

Metal clip processing is not a complicated process, but as we always aim for satisfactory customer feedback, we strictly control each detail of product quality in the production processing. For highly qualified metal clips, please do not hesitate to contact us, as we will design and produce the most suitable products and provide custom services based on your needs.

Processing range- Materials: low-carbon steel, stainless steel, manganese steel, beryllium copper, brass, nickel alloy, tinplate, etc.

- Thickness: 0.3mm~1mm

- Width: above 2mm

- Length: above 15mm

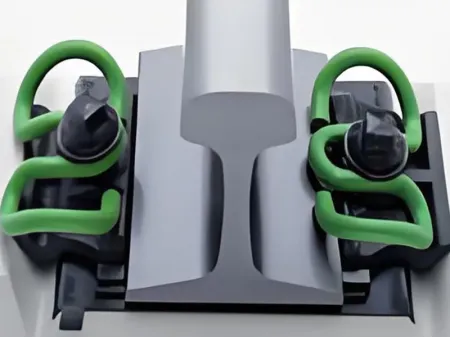

- Metal Clips

- Metal Clips

- Metal Clips

- 65mm Metal Clips

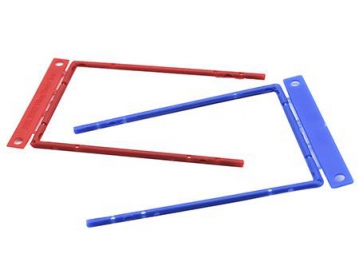

- metal U clip

- ring binder

- wire bender clip