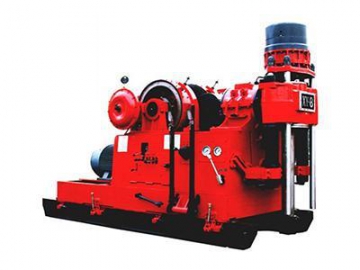

Spindle Type Core Drilling Rig

Choosing a right drilling rig is important for coring. Generally, core drilling rigs should be chosen according to design depth of drilling, design angle of drilling, rock conditions, and drilling methods etc. Here we give you some examples as follows:

Diamond core drilling requires hydraulic drilling rigs with higher speed and wider range of speed regulation. Besides, the drilling rigs should be equipped with bottom hole pressure gauge, speed and torque meter. When driven by electric motor, core drilling rigs should be fitted with voltage meter and ammeter.

When creating holes in the alluvial layer, stack layer or loose sandy land, blade bits or common carbide drill bits can be used. The mud can be used as washing fluid.

Impact bits are suitable for drilling into gravel layer. Drilling after cement injection or orifice tube embedment is also applicable.

When drilling in hard rock, you should use carbide drill to drill a hole of 300mm depth, and then use diamond-impregnated bit.

As a professional core drilling rig manufacturer in China, we produce core crawler drilling rigs, core trailer drilling rigs, and full hydraulic core drilling rigs for you to choose from. These products are reliable, versatile, and come in various specifications to satisfy your different drilling applications.

Geological drilling rigs are often used for coring, which retrieve core samples from the ground. Reprehensive core and rock debris are often obtained to help determine the subsurface geology and amount of mineral resources.

We manufacture core drilling rigs including spindle type and full hydraulic type for a wide range of applications: solid mine bed exploration drilling with the depth of 100-4200 meters, engineering geological exploration, superficial-zone petroleum and natural gas mining, mine gallery ventilation and water discharge tunnel drilling. And according to the customer need, the rig can be mounted on skid, crawler or truck.

core drilling rigs- spindle type is ideally suited for exploration, mining, water well and pile grouting hole drilling operations projects for which ease of transport, mobility and compact dimensions are important factors.

| Technical Parameters | |||||||||

| Model | XY-1 | XY-200 | XY-2B | XY-3B | |||||

| EURO standards | U.S. standards | EURO standards | U.S. standards | EURO standards | U.S. standards | EURO standards | U.S. standards | ||

| Drilling capacity | 110m | 361feet | 280m | 656feet | 300m | 984feet | 600m | 1968feet | |

| Hole diameter | Φ75-Φ110mm | Φ3-Φ4.3inch | Φ60-Φ380mm | Φ2.4-Φ15inch | Φ80mm-Φ520mm | Φ3.1-Φ20.5inch | Φ75mm-Φ800mm | Φ3-Φ31.5inch | |

| Max torque | 0.6knm | 443lbf.ft | 1.7knm | 1254lbf.ft | 2.55knm | 1881lbf.ft | 3.5knm | 2618lbf.ft | |

| Angle range | 90°-75° | 90°-75° | 0°-90° | 0°-90° | 90°-70° | 90°-70° | 90°-70° | 90°-70° | |

| Spindle max pull force | 25kn | 5620lbf | 49kn | 11016lbf | 68kn | 15287lbf | 68kn | 15287lbf | |

| Spindle stroke | 450mm | 18inch | 510mm | 20inch | 550mm | 22inch | 550mm | 22inch | |

| Hoist max lift capacity (single rope) | 10kn | 2248lbf | 20kn | 4496lbf | 25,15,7.5kn | 5620,3372,1686lbf | 30kn | 6744lbf | |

| Power unit | Electric motor | 7.5kw | 10hp | 22kw | 30hp | 30kw | 40hp | ||

| Diesel engine | 10.3kw | 14hp | 20kw | 27hp | 24.6kw | 33hp | 35.3kw | 47hp | |

| Rig weight (without power unit) | 500kg | 1102lb | 1000kg | 2205lb | 1200kg | 2646lb | 1300kg | 2866lb | |

| Model | XY-4 | XY-4T | XY-5 | XY-6 | |||||

| EURO standards | U.S. standards | EURO standards | U.S. standards | EURO standards | U.S. standards | EURO standards | U.S. standards | ||

| Drilling capacity | 850, 1200m | 2789,3937feet | 700-1000m | 2297-3281feet | 900-1800m | 2953-5905feet | 1000-2400m | 3281-7874feet | |

| Hole diameter | Φ42mm,Φ50mm drilling rod | Φ1.7,Φ2 inch drilling rod | Max 110mm | Max 4.3inch | Max PQ drilling rod | Max PQ drilling rod | Max PQ drilling rod | Max PQ drilling rod | |

| Max torque | 2.64knm | 1947lbf.ft | 2.64knm | 1947lbf.ft | 5.5knm | 4057lbf.ft | 7.8knm | 5753lbf.ft | |

| Angle range | 0°-360° | 0°-360° | 90°-45°(360°) | 90°-45°(360°) | 90°-75°(360°) | 90°-75°(360°) | 90°-75°(360°) | 90°-75°(360°) | |

| Spindle max pull force | 80kn | 17985lbf | 80kn | 17985lbf | 135kn | 30349lbf | 200kn | 44962lbf | |

| Spindle stroke | 600mm | 24inch | 600mm | 24inch | 500mm | 20inch | 600mm | 24inch | |

| Hoist max lift capacity (single rope) | 30kn | 6744lbf | 30kn | 6744lbf | 60kn | 13489lbf | 85kn | 19109lbf | |

| Power unit | Electric motor | 30kw | 40hp | 30kw | 40hp | 55kw | 74hp | 75kw | 101hp |

| Diesel engine | 31kw | 42hp | 30kw | 40hp | 60kw | 80hp | 85kw | 114hp | |

| Rig weight (without power unit) | 1500kg | 3307lb | 4200kg | 9259lb | 3100kg | 6834lb | 3650kg | 8047lb | |

Main Features

- Hydraulic rising

- Higher rotational speed

- Easy and convenient operations

- Light weight, easy removal

- Reliable hydraulic system

- Suitable for different Geological exploration

- Convenient for maintenance

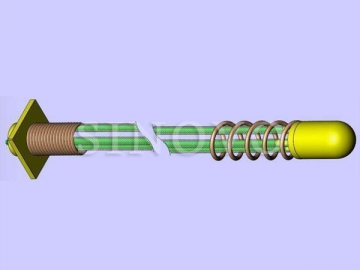

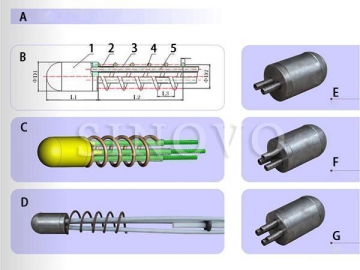

A. OQM-d Series Retrievable Anchorage Cable

B. Sectional View

1. Supporting Part

2. Connector

3. Plastic Pipe

4. Coil

5. Steel Strand

C. 3D Drawing

D. Product Photo

E. 2 holes

F. 3 holes

G. 4 holes