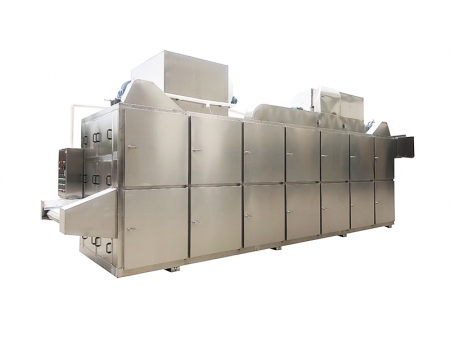

Atomizing Granulating Drying Machine

Descriptions

The

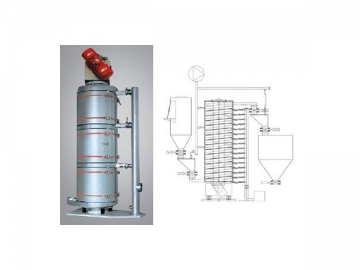

The tower body, pipes and separator of the atomizing granulating dryingmachine, which come into contact with the raw material, are made of SUS304.There are multiple layers of glass fiber insulation between the inner and outercase of the tower body, which increases the efficiency. The tower body is alsoequipped with an observation door, lamp-house, control meters, and instrumentsthat control and display on an electric control panel.

1. The drying speed is very fast. Thesurface area of liquid raw materials after being atomized is greatly increased.95-98% of the moisture is quickly evaporated. The time of drying is completedin ten seconds or more. The atomizing granulating drying machine is suitablefor drying heat sensitive material in particular.

2. The finished product is pelletized with a uniformsize. The purity of the finished product is high and of high quality.

3. The scope of application is vast. According to the characteristics of theraw materials, it can use hot air to dry and it can use cool air to granulate.It has great adaptability to raw materials.

4. The atomizing granulating drying machine operation is simple, easy tocontrol, and convenient, and it is possible to achieve automatic operation.

Application ofthe AtomizingGranulating Drying Machine

Granulating Through Dry Atomizing

Chemicalindustry: organic catalyst, resin, synthetic washing powder, oils,thiamin, dyestuff, intermediate of dyestuff, white carbon black, graphite,ammonium phosphate, and so on.

Foodstuff:

Pharmaceutical:Chinese patent medicines, agrochemicals, antibiotics, medicaldrinking dosage, and so on.

Ceramics:

Technical Parameters of the Atomizing Granulating Drying Machine

| Item model | PG-Y-25 | PG-Y-50 | PG-Y-100 | PG-Y-150 | PG-Y-200 | PG-Y-300 | PG-Y-500 | PG-Y 1000-2000 | |

| Evaporated amount(Kg/h) | 25 | 50 | 100 | 150 | 200 | 300 | 500 | The index can be affirmed in accordance with practical conditions. | |

| Diaphragm pump | Power (kW) | 0.35 | 4 | 7.5 | 11 | 15 | 22 | 30 | |

| Pressure (Mpa) | It can be regulated from 0.6 to 5; in general, it will be from 1 to 3. | ||||||||

| Heating way | electricity | Electricity steam | Electricity coal fuel(oil) hot air furnace | ||||||

| Diameter of tower body (mm) | 1300 | 1800 | 2400 | 2600 | 2800 | 3200 | 3800 | ||

| Total height of equipment (mm) | 7800 | 9200 | 11600 | 14000 | 15300 | 17100 | 19000 | ||

Note

1.The evaporated amount is related to characteristics of rawmaterial. The evaporated amount listed in the table is related to temperature.This data should be used for reference only.

2. The atomizing pressure and model of pump should be chosen in accordance withthe amount of raw material to be treated and the size requirement of thefinished product.

3. The power of the fan should be increased if after equipped with cloth bagduster.

As aspecialized atomizing granulating drying machine manufacturer and supplier inChina, we also offer fluidizing drying equipment, belt drying equipment, circlevibrate sieve, granulating coating machine, and others.