Food Aseptic Workshop Manufacturer

Food Aseptic Workshop Manufacturer

The food aseptic workshop is a small room set specially in the microbe laboratory. It is often made of EPS plate. The plant is often built with the area of 4 to 5 square meters and the height of

Meanwhile, the buffer room and aseptic room should be airtight. The ventilation equipment in the room should be furnished with air filter. The wall and the floor of the aseptic room should be flat to prevent dust and contamination as well as facilitate washing. The surface of the operational table should be horizontal. The ultraviolet lamps are equipped to the buffet room and aseptic room. And the distance between the lamp and workbench in the aseptic room should be

Nowadays, the aseptic workshop is mostly applied in the microbial technological factory. For the ordinary laboratory, clean bench can meet the basic requirements for working environment. The clean bench can remove various microscopic dusts including microbe on the operational table through the laminar air flow device. Through the action of electric device, the air can pass the high efficiency filter and enter into the workbench. Then the operational table can be in the aseptic state. Meanwhile, there is a high speed air flow curtain close to the exterior part for preventing the outer contaminated air going into the clean bench.

The aseptic technique plays a very important role not only in the research and application of microbiology but also in the fields involving in many biotechnologies such as the technologies of transgene and monoclonal antibody.

Cautions

1. The operator should turn off the ultraviolet lamp first after entering into the food aseptic workshop. Meanwhile, the rules for aseptic operating should be obeyed strictly to avoid microbial contamination.

2. There are aseptic operating room and buffer room for the aseptic room. The cleanliness for the aseptic operating room should get to the level of 10000. Meanwhile, the interior temperature and the humidity should be kept in the range of 20 to

3. The aseptic room should be kept clean from the unrelated stuff to avoid contamination. And all the sterilization equipment and medium should be in the aseptic state. In addition, the contaminated devices cannot be used in the operation.

4. The food aseptic workshop should be sterilized with the suitable disinfectant in a regular time to assure its cleanliness meeting the requirements.

5. All the things, such as instrument, devices and the plate, needed to be brought into the aseptic room should be packed tightly and disinfected with the suitable method.

6. Before entering into the aseptic room, the working staff should wash and disinfect hands with soap or disinfectant and wear the work clothes, shoes, hat, mask and gloves. The gloves can also be replaced by cleaning hands with the 70% ethanol again.

7. Before using the aseptic room, the ultraviolet lamp should work for at least 30 minutes to achieve irradiation sterilization. Meanwhile, the clean bench should also be opened to blast air. After finishing the operation, the operator should clean the aseptic workshop immediately and open the ultraviolet lamp for 20 minutes.

8. Before inspection, the test sample should be kept with whole external packing from contamination. Meanwhile, the 70% ethanol should be employed to disinfect the exterior surface of the test sample.

9. The articles with viable organism should be sterilized first and then washed with water to avoid contaminating the sewer.

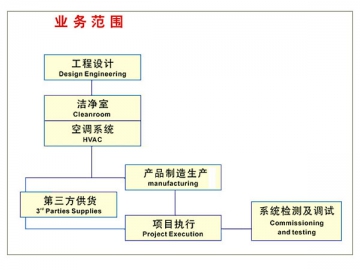

Business Scope

Engineering Design

Clean Room

HAVC

Material Supplying by the Third-party

Product Manufacturing

Project Implementation

System Inspection and Debugging

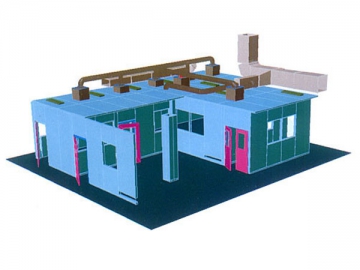

Simulation System for Clean Room

Baking Room | Baking Room | Baking Room |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||