Automotive

Target Customers

Auto mold agents, auto parts manufacturers, automotive assembly plants, and auto design, research and development institutes

Valued Partners

Our partners include Volkswagen, Audi, Dongfeng Motor, Citroën, Changchun Railway Vehicles, Hafei, Iveco, and Chery.

Scope of Services

A. We design, manufacture, inspect, install, and service auto molds.

B. We provide compression molded fiberglass plastics and injection molded parts for use in auto manufacturing. Here we've listed some of the auto parts that can be made through compression molding and injection molding.

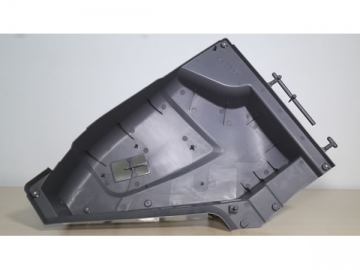

Exterior Car Trims: bumper covers, mud flaps, wheel wells, spoilers, fenders, and liftgates

Interior Car Trims: instrument panels, car door panels, sub-dash panels, glove boxes, and car seats, among other various protective panels

Functional or Structural Parts: petrol tanks, coolant reservoirs, air filter covers, fan blades, air intake hoses, and cylinder heads

Advantages

After 14 years serving the car mold industry, Haiyee is an experienced manufacturer of trims, body panels, and structural members for cars of any model and make. Our expertly trained designers are able to design optimized automotive molds that meet customer's exact specifications. The use of imported equipment gives us control over the machining precision of the molding tools.

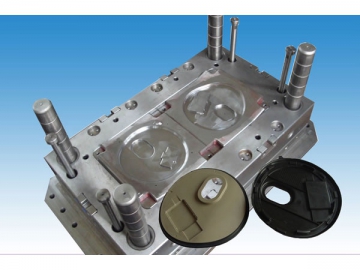

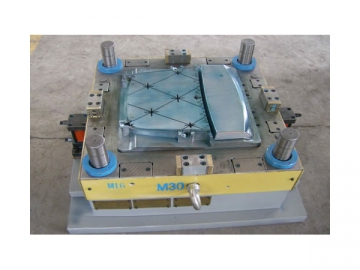

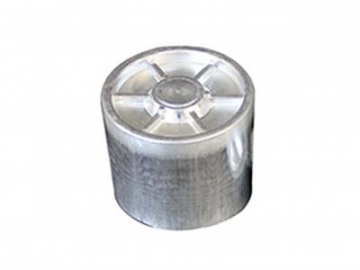

Mold Showcase

Below are some of our auto molds provided to customers in the automotive industry.

Molded Products Showcase

For auto parts agents, designers, or automotive producers lacking manufacturing equipment, Haiyee can design molds and run them to produce compression molded and injection molded parts. Using SMC fiberglass, we can compression mold auto parts that outperform molded parts from other materials in terms of mechanical strength, surface finish, electrical and thermal insulation properties, and resistance to oxidation. No wonder our compression molds are the top choice for many auto dealerships, body shops, and manufacturers.