Car VOC Testing and Analysis System (Volatile Organic Compound and Odor Testing)

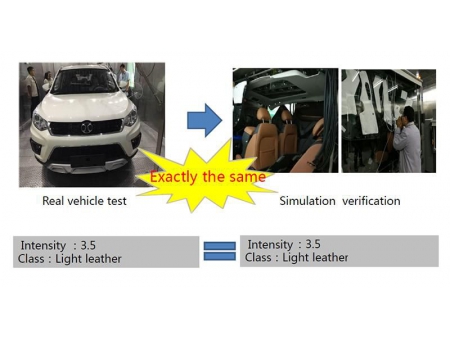

Car VOC/Odor Testing and Analysis System is designed for automotive design process, which provides standard testing environment or simulates a real environment to test volatile organic compound and odor for auto part samples and vehicle samples during early stage of new vehicle development. Traditional VOC testing is delivered by semi-reverse engineering, which always encounters interior air quality system problems in the middle or late stage of new vehicle development when auto part molds, part material and part processing technologies are fully completed, a high improvement difficulty, high cost and low efficiency will be generated. Simplewell adopts an automatic VOC testing system, featuring forward engineering, to solve the above problems.

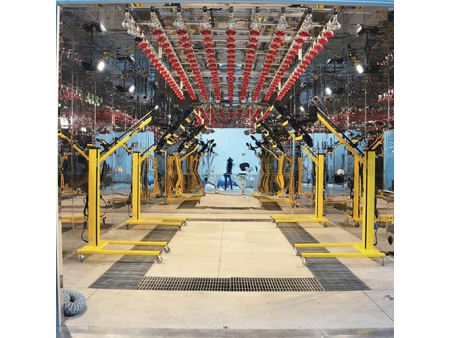

A 5.25m3 clean chamber is designed to be the test chamber for whole vehicles of different standards.

A 2m3 clean chamber is designed to screen out unqualified part or part units.

After placing samples within test cabinet, it should be cleaned in advance by starting interior cleaning & filtering system before VOC and odor test being activated. And when it is finished, turn off the cleaning system and activate the VOC and odor testing. If there is any problem, screen chamber will be adopted to screen out the unqualified auto parts and part units, whose testing is carried out one by one. In this way, parts’ influence towards vehicle will be well measured and proper improvement towards automotive design process will be delivered.

| Project | 2&5M3 chamber | Sampling bag | 1M3 chamber | Note | |

| functional test | VOC and odor testing for whole vehicles | √ | × | × | New function |

| Odor testing for auto parts | √ | × | √ | ||

| VOC testing for auto parts | √ | √ | √ | ---- | |

| Simulated sunlight testing | √ | × | × | New function | |

| Powertrain's adaptability | √ | √ | × | --- | |

| Environmental factor adjustment | Temperature adjustment | √ | - | √ | --- |

| Humidity adjustment | √ | - | √ | --- | |

| Environmental background value's stability | √ | √ | √ | --- | |

| Cost effectiveness | Low | Medium | High | --- | |

| Efficiency | High | High | Low | --- | |

| Accuracy | High | Low | High | --- | |

| Model | | |

| Working temperature | 5℃~35 | |

| Working humidity | ≤90%RH | |

| Cleanliness | No pollution source in surrounding | |

| Environmental chamber capacity(W*D*H)mm | 910*2000*1100(130*2400*640) Different dimensions for different parts | 2500*1400*1500 |

| Test chamber door size (H*W)mm | 2000*1100(2400*640) | 2500*1400 |

| Temperature adjustment | 20-30℃ with a humidity of 40--60% R.H. 23℃ with a humidity of 45%R.H. 25℃ with a humidity of 50% R.H. | |

| Humidity adjustment | 40~70%RH(20~30℃), 5%(65℃) | |

| Temperature fluctuation | ±0.3℃ | |

| Temperature tolerance | ±1.0℃ | |

| Humidity tolerance | ±2.5%RH | |

| Humidity tolerance | ±3%RH | |

| Air change rate | 0.2~5 time/h±5% (Larger air change rate is optional), sealed | |

| Power supply | AC 380V/50Hz Three-phase four line or three phase five line | |

| Recovery rate | A recovery rate of more than 80 for formaldehyde, octanol, tetraphenylethylene, dodecane, and tetradecane. | |

| Clean energy system | Optional configuration | |

| Infrared heating test | 1. Irradiation with infrared lamp 400W/M2 . 2. Infrared heating with a temperature of 40 ℃or 65 ℃. | |

| Background value in load-free chamber | After switching on the cleaning system for 30 min, the content of VOC is lower than 5mcg/m3, TVOC lower than 50mcg/m3 , and formaldehyde, acetaldehyde, acrolein lower than 15 mcg/m3. After heating it for two hours with a constant temperature of 65℃, the content of benzene, toluene, ethylbenzene, xylene, styrene will be lower than 20mcg/m3. | |

- A. Environmental chamber: providing a clean and constant temperature environment for test chamber, as well as an indirect controlling towards the temperature and humidity within test chamber, thus to achieve a stable testing effect;

Air jacket: controlling the temperature, humidity and cleanliness in environmental chamber

Buffer room (Optional): operators, instrument, maintenance staffs

Temperature control system: temperature controlling towards environmental chamber, indirect controlling towards the temperature and humidity within test chamber

Discharging system: environmental chamber and test chamber

Lightening

Door: allowing the entrance of personnel, instruments and maintenance staffs - B. Test chamber: (one set of 5.25m3 chamber), designed for whole vehicle testing

- C. Test chamber: (two sets of 2m3 chamber), designed for auto part testing

- D. Air purifying system: designed to test formaldehyde, VOC (volatile organic compounds), odor test, as well as to provide clean air to test chamber (clean air supply is optional)

Test chamber is outfitted with at least one odor sampling port, allowing air’s compensation during odor sampling, which helps to avoid the polluted air entering test chamber due to the pressure difference inside and outside of the chamber. Besides, for the same reason, a filtering device is also outfitted outside the test chamber. These devices’ installation does not only help to achieve odor sampling in both air exchanging condition or sealing condition, an interference caused by diverse environmental factors or other uncertain factors could also be well prevented.

Details about Car VOC/Odor Testing and Analysis System:- GB/T27630-2011 guideline for air quality assessment of passenger car was launched by ministry of environmental protection and national bureau of quality inspection. After that, interior air quality becomes one of the hot issues in the field. Therefore, many automotive manufacturers start to place their emphasis on the controlling towards automotive interior air quality.

- But now, most of the automotive manufacturers adopt a reverse engineering method for automotive design, which means that a VOC testing towards auto parts and whole vehicles will be carried out in the medium or late stage of automotive development.

- That is to say, if the interior auto nonmetal parts are unqualified for national requirements towards VOC testing, a rectification will be carried out for the satisfaction of enterprise standards. Afterwards a VOC testing will be delivered again. This process will repeat for several times until its performance is fully qualified. Since many problems related to interior air quality system could only be encountered in the middle or late stage of new vehicle development when part molds, part material and part processing technologies are fully completed, high improvement difficulty, high cost and low efficiency will be generated. Under this circumstance, Simplewell adopts an automatic VOC testing system, featuring forward engineering, to solve the above problems.

- Automotive odor, VOC (volatile organic compounds) testing system is made of stainless steel plate, whose surface adopts a low-absorption coating, allowing an improvement on its internal absorption. Besides, a solar simulation system with infrared ray simulating sunlight is also adopted for the controlling of both temperature and irradiance.

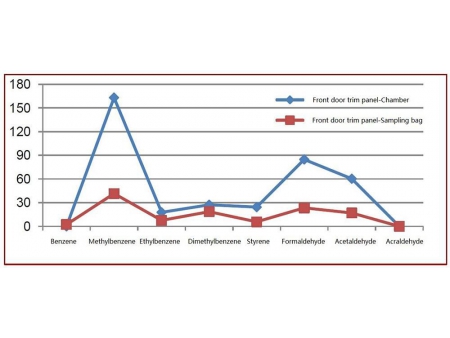

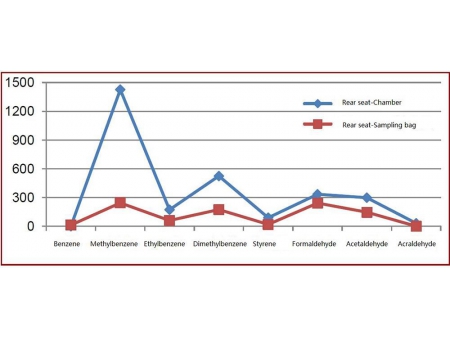

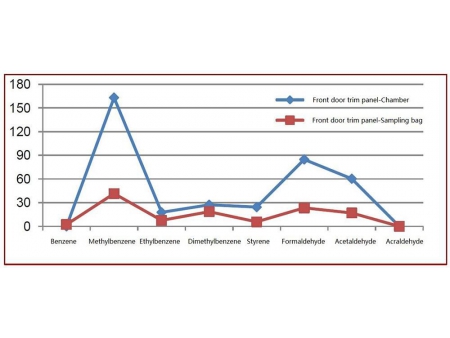

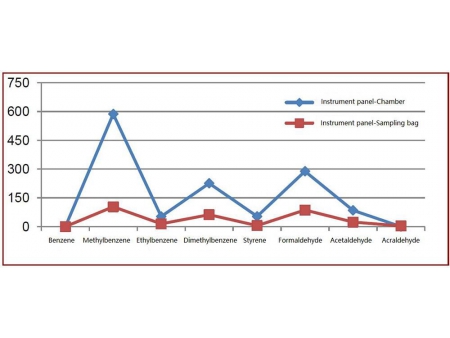

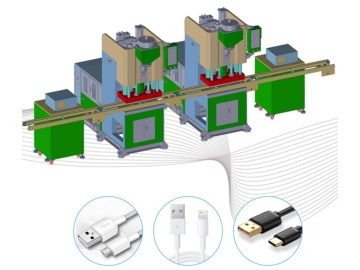

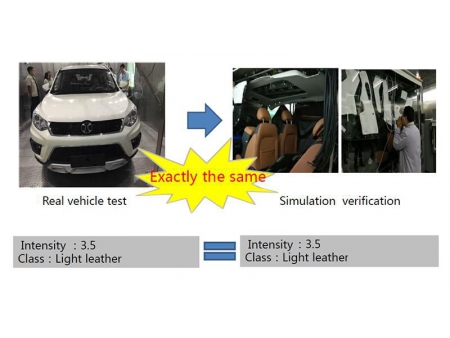

Parameters displayed on the VOC testing system well simulate the vehicle’s condition, and stand for the related data of hazardous substances released by auto parts. In this way, the odor releasing amount of different auto parts in different conditions could be well displayed. Therefore, the system is quite suitable for the testing towards formaldehyde, particles, VOC, ozone, odor, NOx, sulfur oxides and ammonia gas. In addition, as an alternative towards sampling bag, Simplewell’s Car VOC/Odor Testing and Analysis System could also be used in forward engineering of other industries, such as other vehicles, home remodeling and so on.