CNC Machining Service

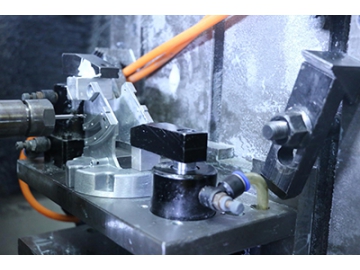

We have 7 sets of CNC machining centers with a maximum machining size of 600×300mm and machining accuracy within 0.03mm. They can meet the fine machining requirements of most products. Equipped with a 4th axis rotary table, the CNC machines can complete one-time machining of products with multiple sides. This minimizes the risk of positioning errors due to multiple clamping during machining.

CNC machining is of vital importance in the fine machining process of die castings. Generally, the following machining processes are carried out.

- Milling

- Boring

- Drilling

- Tapping

- Thread cutting

After receiving drawings, we have experienced designers meticulously check drawing requirements including surface finish, dimensional tolerance etc., so as to meet fixture design and manufacturing standards.

In addition, the die castings for machining can be processed with further fine machining processes to facilitate direct application of components.

- Heat treatment

- Deburring

- Galvanizing

- Powder coating

- Polishing/ Electrolysis

- Other protective coatings

- Special protective package