Condensing Unit

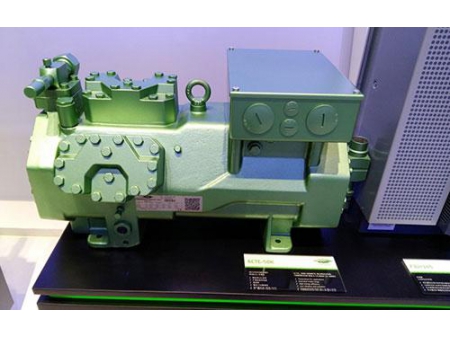

Howcool chooses only the highest quality and most reliable refrigeration units to ensure the application effect in a cold storage room to meet customer requirements. Because the refrigeration unit is the most important component of cold storage, we import units from internationally known brands, including Bitzer, Emerson Copeland, Frascold or RefComp. We also choose practical and cost effective brands such as Hanbell or Fusheng.

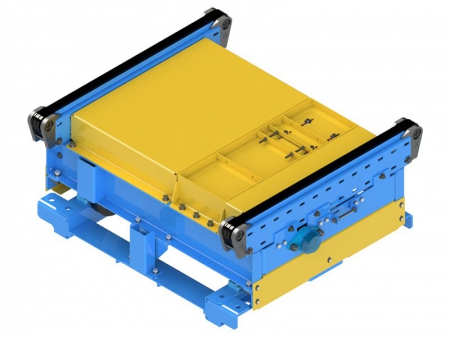

- Bitzer 6CTE-50K Compressor

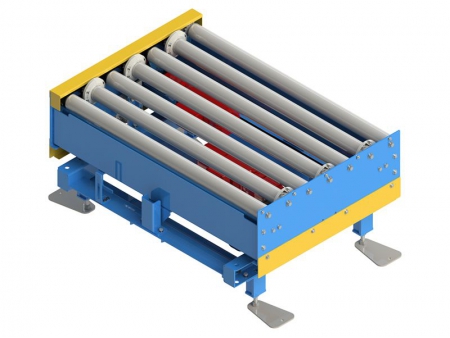

Bitzer 4FE-28Y Compressor

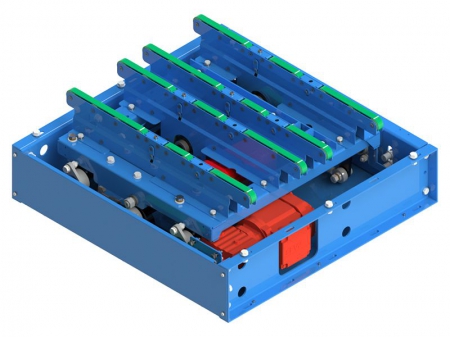

Bitzer 4FE-28Y Compressor

| Compressor model | 50-300P |

| Refrigerant | R404A, R507C |

| Motor voltage | 380/420V,50Hz |

| Noise value | 60- 80dB (A) |

| Cooling capacity range | 1KW-500KW |

| Condensation | air-cooled and water-cooled |

| COP value | 2.3-2.5 |

| Protection level | IP54 |

| Lubricant | BSE32 |

| Energy regulation | 25%,50%,75%,100% |

| Refrigeration conditions | -40~15 ℃ |

| Unit | Bitzer reciprocating compressor |

| Rated power | 2P-40P |

| Applicable condition | Middle temperature |

| Scale of cold storage | lower than 2000m3 |

| Adaptable power supply | 380V/415V |

| Advantage | box type, low noise, stable operation |

| Main unit | Bitzer reciprocating compressor |

| Rated power | 2P-40P |

| Applicable condition | medium temperature |

| Scale of cold storage | lower than 2000m3 |

| Adaptable power supply | 380V/415V |

| Advantages | box type structure, low noise, stable operation |

| Main unit | Bitzer reciprocating compressor |

| Rated power | 50-300P |

| Applicable condition | low temperature |

| Scale of cold storage | lower than 30000m3 |

| Adaptable power supply | 380V/415V |

| Advantages | Protection device for failure conditions such as overheat, overload and low level of oil, giving it an excellent security. |

| unit | Bitzer screw compressor |

| Rated power | 50-300P |

| Applicable condition | high temperature |

| Scale of cold storage | lower than 30000m3 |

| Adaptable power supply | 380V/415V |

| Advantage | Protection device for failure conditions like overheat, overload and low level of oil, giving it an excellent security |

(1) Temperature range

When choosing a compressor, the temperature requirement for refrigeration equipment should first be considered.

Because motor powers and gas flows are different depending on different working conditions, medium and high temperature compressors and low temperature compressors with the same displacement are designed and manufactured using different motors and valve plates respectively. We will investigate the customer's usage conditions, then choose a suitable compressor for their needs.

For example, a low temperature compressor is not suitable for conditions where the evaporating temperature is more than -5 ℃, in order to avoid compressor overload. Conversely, when a high temperature compressor with the same displacement is used in low temperature conditions, the refrigeration equipment cooling capacity is reduced and power consumption is significantly increased due to the decrease in motor efficiency and power. This lack of an economic performance is why choosing the right compressor for your needs is so important.

the main unit is a Bitzer semi-hermetic compressor, and the power arrange is 20-250HP.

(2) Refrigeration Capacity

The refrigeration capacity will directly affect the initial monetary investment, equipment space, energy consumption and economic effects of the project.

Traditionally, the refrigeration capacity is based on the customer's heat load, though actual situations are different. Two factors need to be considered: the one time investment and working economic effect. Different customer usage habits and different energy prices in different areas will directly affect both of those factors.

Therefore, the designer must fully investigate the local actual situations and directly carry out an economic analysis by hand instead of using a formula and applying data. A poor design consideration will not only cause maintenance problems, but it will also reduce the efficiency and lead to the potential for accidents.

wind enters from two sides and exits the top for a high refrigeration efficiency.

(3) Energy regulation

Usually, the compressor selection depends on the maximum refrigerating capacity of system. In practice, it is necessary to adjust compressor energy to reduce the temperature fluctuation. There are many methods of energy regulation, such as hot gas bypass regulation, variable frequency speed regulating device, single compressor running intermittently, and multi-cylinder compressor regulated by sealing two cylinders per gear. However, there is a risk of problems such as insecurity, high costs or high energy consumption.

Through production practice, Howcool is familiar to multi-units system mounted in a parallel manner gradually. Using multiple compressors in a parallel manner to replace a single large capacity compressor, users can ensure the efficiency of the refrigeration equipment in a partial load in order to save energy. At the same time, multiple machines starting one by one also avoids a large impact on power grid, improving safety. What's more, when one compressor breaks down, system running still can be maintained during its repairing.

The number of systems chosen should be done based on comparisons and analytics of customer conditions. Based on our experience, we believe that to achieve the best possible performance that is the most energy efficient, the number of compressors should be as few as possible in order to simplify both the system and operation. However, the total number of units should not be less than 2, in order to ensure an effective adjustment of the cooling capacity when the heat load is changing, and ensure system operation with single compressor during inspection periods.