Copper

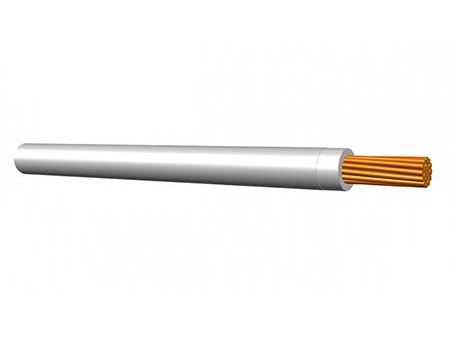

Because of remarkable ductility and corrosion resistance, cupper, bronze and brass were the common temporal metal materials before steel. Cupper features high ductility, conductivity and thermal conductivity, hence is widely used as the materials of tubes, anticorrosion parts and electric wires in military and electric power industry, etc.

It's not difficult to deal with simple copper products while complicated or smooth precision parts require various finishing machining beyond regular processes, which needs vibratory deburring machine, centrifugal finishing machine, centrifugal barrel polisher and other machines.

Brass is the alloy of copper, zinc and other microelements. Brass, featuring golden luster, can achieve certain strength by adjusting the proportion of microelements. Because of very low friction coefficient, it is the ideal options for locks, bearings, shells, valves, instruments, sanitary equipment, electrical equipment and other products. Many manufacturers of OEM, aerospace industry and automotive industry utilize vibratory deburring or centrifugal polishing to finish the cupper products.

Bronze is the alloy with 12% tin, featuring higher hardness than brass, which is applicable to finishing harder tools, such as weapons, high strength bearings, shaft sleeves, strings, gears and other wear-resisting components. Bronze is an ideal option for the deburring and polishing of the mass finishing products.

With decade years of experience in polishing equipment, Kafan is the best option for the weapon, precision parts and OEM manufacturers. If you have need in finishing the copper, bronze or brass products and are confused about finishing types, you are welcome to send us the samples. Kafan will provide you with the customized suggestions and directions.