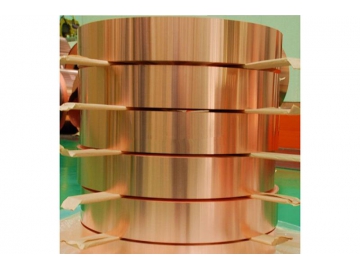

Copper Strip

Copper with a purity of 99.5% to 99.95% is commonly referred to as pure copper or red copper due to its reddish hue. The primary composition consists of copper and silver, with trace amounts of elements such as phosphorus, bismuth, antimony, arsenic, iron, nickel, lead, tin, sulfur, zinc, and oxygen.

This high-purity copper is widely used in the production of electrical components, high-grade copper alloys, and copper-based materials due to its excellent conductivity and durability.

Pure copper is classified into T1, T2, and T3 grades. We collaborate with specialized copper manufacturers to supply aluminum-copper alloys and brass in various forms, including sheets, rods, tubes, and wires.

Chemical composition (%)| ASTM | Composition (%) | ||||

| Cu Ag | P | O | Other | ||

| C10200 | 99.95 | 0.001-0.005 | - | balance | |

| C11000 | 99.9 | - | - | balance | |

| C12000 | 99.9 | 0.004-0.012 | - | balance | |

| C12200 | 99.9 | 0.015-0.040 | - | balance | |

| Grade (China) | Grade (Japan) | Temper | External Diameter/mm | Tensile Strength Rm MPa | Elongation A (%) | Hardness | |

| No less than | HV | HBW | |||||

| T2 TU1 TP1 TP2 | C1100 C1020 C1201 C1220 | O60 | All | 200 | 41 | 40-65 | 35-60 |

| O50 | All | 220 | 40 | 45-75 | 40-70 | ||

| H02 | No more than 15 | 250 | 20 | 70-100 | 65-95 | ||

| H04 | No more than 6 | 290 | - | 95-130 | 90-125 | ||

| More than 6-10 | 265 | - | 75-110 | 70-105 | |||

| More than 10-15 | 250 | - | 70-100 | 65-95 | |||

| H06 | No more than 3 | 360 | - | No less than 110 | - | ||

- Thickness: 0.005 mm – 2.5 mm

- Width: ≤ 610 mm

- Coil Weight: ≤ 3 tons

- Length: 1 – 12 m, available in coils or custom lengths upon request

Applications

Copper strips are used in the production of deep-drawn and bent stress components, making them suitable for various industrial applications. Common uses include the manufacturing of pins, rivets, washers, nuts, tubing, pressure gauge springs, mesh screens, and heat dissipation components.

Index

metal strip, strip coil