Auto Parts Welding Solution

Car motor leading wire welding machine

| Item | Height | Length | Width |

| Size | 2420 | 1800 | 1350 |

| Item | Parameter |

| Rated Capacity (KVA) | 220 |

| Power Supply (V/φ/HZ) | 380/3P/50HZ |

| Max Input Current (A) | 120 |

| Rated Duty cycle (%) | 20 |

| Secondary empty Voltage (V) | 10.4 |

| Secondary voltage adjust level | 1 |

| Throat Depth (mm) | 420 |

| Arm Gap (mm) | 246 |

| Cylinder Stroke (mm) | 120 |

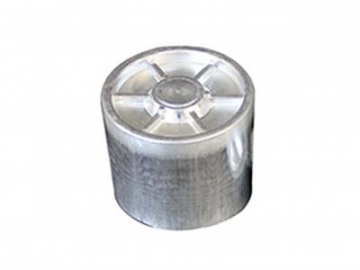

| Electrode Size (mm) | 100*8*8 |

| Workpiece Size (mm) | Ф35 *72 |

| Welding Speed (s/ piece) | 10 |

| Max Working Pressure (N/0.5MPa) | 6000 |

| Compressed Air Pressure (MPa) | 0.6 ≦P≤0.8 |

| Compressed Air Consumption (L/ welding spot) (0.4MPa,Stroke 30mm ) | 3.56 |

| Cooling Water Consumption (L/MIN) | 12 |

| Primary Cable Specification (MM2) | 3*35+2*16 |

| Max. Short Circuit Current (KA ) | 4000 |

| Dimensions (L*W*H) (mm ) | 1800*1350*2420 |

Feature

1. The Heron car motor welder is delivered in 220KVA or 440KVA MFDC power supply models.

2. The working head can be outfitted with a moving fixture for precise positioning up, down, left, or right

3. The workpiece can adopt moving fixture for up, down, left or right with precise positioning.

Background introduction

The car motor welder is a copper wire welding machine was introduced by our company for connection of electric car motor wires. The welder gasifies oil paint of varnished wires through a quick heating process for terminals. Secondly, it melts the copper wire and terminal by increasing its current in order to realize reliable welding quality. The welding technology is different from processes that polish the oil paint and then plate the wire with tin. This improves overall quality and working efficiency.