Water pump housing nut resistance welding system

Main technical parameter

| Item | Parameter |

| Power Supply (V/¢/HZ) | 380/3/50 |

| Discharge transformer power (KVA) | 2*500 KVA |

| Capacitor | 60pcs of 2000μF/1000V capacitor |

| Max primary current (A) | 210 |

| Primary cable (m㎡) | 50 |

| Rated duty cycle (%) | 50 |

| Secondary empty voltage (V) | 18-23.5 |

| Welding cylinder size(¢*L) | φ250*150 |

| Max working pressure(N) | 48000 |

| Compressed air pressure (MPa) | 0.6-0.7 |

| Cooling water consumption(L/MIN) | 10 |

| Dimensions (L*W*H) MM | 3500*2100*3000 |

Feature

1. The water pump welder is equipped with 60KJ capacitor discharge welding technology.

2. The welding system requires manual feeding and discharging of the workpieces.

Background information

The welding machine is designed for 1 inch nut water pump housings. The traditional technology used for this process is argon tungsten-arc welding, which has a low efficiency and high labor cost. Our resistance welding technology significantly improves production efficiency and quality.

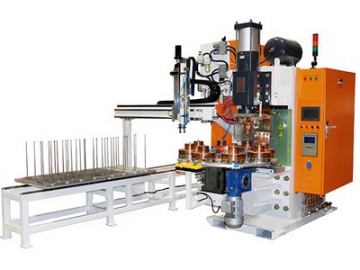

Water pump blade welding machine

Dimensions (unit: mm)

| Item | Height | Length | Width |

| Dimensions | 2550 | 4570 | 2000 |

Main technical parameter

| Item | Parameter |

| rated capacity (uf) | 120000 |

| power supply (KVA/V/¢/HZ) | 135/380/3/50 |

| primary current (A) | 210 |

| rated duty cycle (%) | 50 |

| secondary floating voltage (V) | 18-23.5 |

| Secondary voltage regulating series | 2 |

| arm gap (mm) | 100 |

| cylinder stroke (mm) | 150 |

| welding speed (m/min) (s/piece)(once/s) | 6 |

| Max. Working Pressure (kgf) | 2454 |

| compressed air pressure (MPa) | 0.6~0.7 |

| compressed air consumption(0.5MPaair pressure,stroke:60mm) (L/once) | 28 |

| cooling water consumption (L/MIN) | 10 |

| primary cable specification (MM2) | 50 |

| maximum short circuit current (KA) | 240 |

Feature

1. 60KJ capacitor discharge welding machine.

2. The welding machine adopts an eight station automatic turnplate.

3. Manual workpiece feeding and unloading.

Background information

The welding system is designed for welding water pump blades. It is intended for the replacement of traditional casting technologies. The large welding current is not a problem as we adopt a capacitor discharge welding technology, which significantly reduces the demand for power capacity.

60000J Capacitor Discharge Spot/Press Welder for Water Pump Blade with 8 Station DR-60000-18001

Dimensions (unit: mm)

| Model # | DR-60000-18001 |

| Rated capacity | KJ | 60 |

| Power supply | V/Φ/Hz | 380/3/50 |

| Max. primary current | A | 187 |

| Max. Short Circuit Current | kA | 96.7 |

| Max. working pressure | kN | 29 |

| Dimensions (LxWxH) | mm | 5128x3331x2528 |

30000J Capacitor Discharge Spot/Press Welder for Water Pump Blade with 8 Station DR-30000-18007

Dimensions (unit: mm)

| Model # | DR-30000-18007 |

| Rated capacity | KJ | 30 |

| Power supply | V/Φ/Hz | 380/3/50 |

| Max. primary current | A | 187 |

| Max. Short Circuit Current | KA | 103 |

| Max. working pressure | kN | 18.5 |

| Dimensions (LxWxH) | mm | 3312x2646x2314 |