Gear and Bearing Industry

The raw material used in manufacturing gears and bearings is usually hardened steel, with a hardness range of HRC45-65.

-

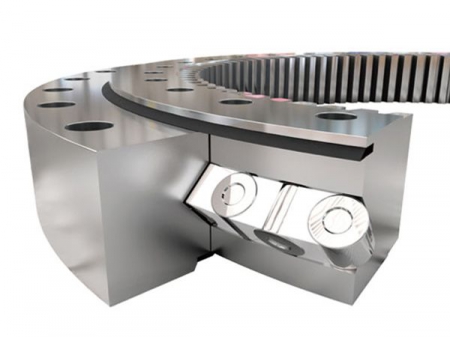

Gear Industry

-

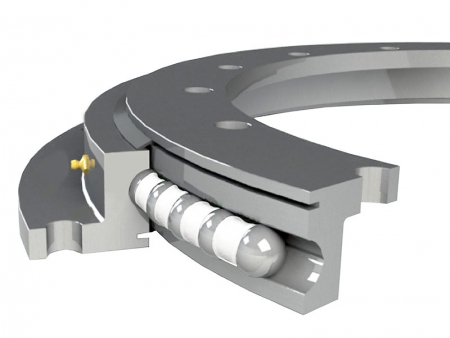

Bearing Industry

-

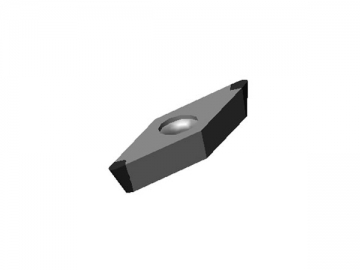

FBS 7000/9300 CNGA1204 series

-

FBS7000/9300 VCGA1604 series

-

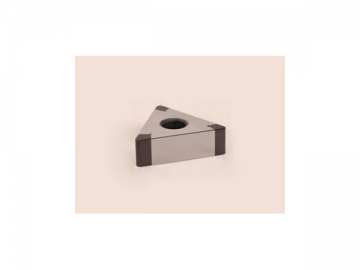

FBS7000/9300 TNGA1604 series

-

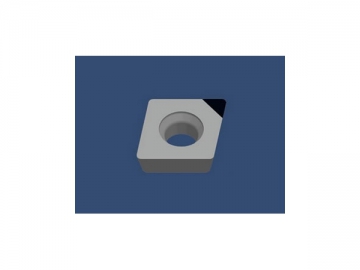

FBK CCGW06/09 series

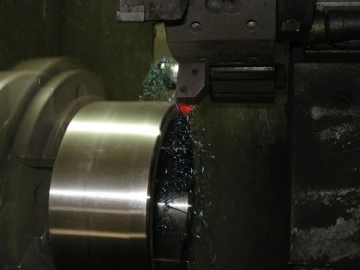

Work piece: addendum circle of gears

Material: 40CrMo

Hardness: HB260-330

Process: heavy-duty roughing

Original cutting tool: imported coated carbide tool 4025 SNMG250720

Current cutting tool: Funik's FBN9000 SNMN201020

Efficiency comparison: 1: 8

Life comparison: 1:10

About the Customer

This customer is a large gear manufacturer located in Luoyang, Henan. Machining the addendum circles of hardened large gears was a discontinuous process. Several imported cutting tools were tried by the customers, all of which worked with a low efficiency and failed to meet output requirements. Rough large gears have high hardness and casting flaws, such as sand inclusion and air holes, making them difficult to turn. The riser on the gear ring is even harder. Through the processing, the cutting edge of carbide tools immediately turn red, and in high cutting temperatures, the edge becomes prone to chipping or breaking. A short tool life was also a common complaint of the tools.

Customer Feedback

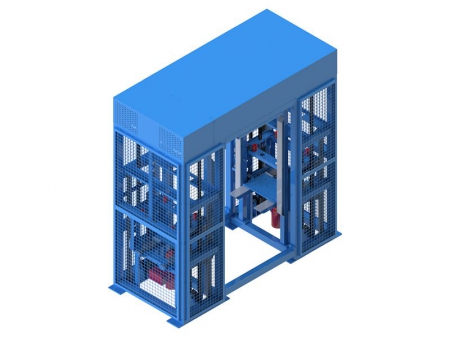

In 2008, we tried Funik CBN cutting inserts, and achieved very good results. We further used the tool for processing more items that are generally difficult to make, such as roller sleeves on high-pressure roller mills, cord reel slots on ship lifts and more. Since 2008, choosing Funik CBN cutting inserts has improved our production capacity about 6 to 8 times more than in comparison with imported coated blades.

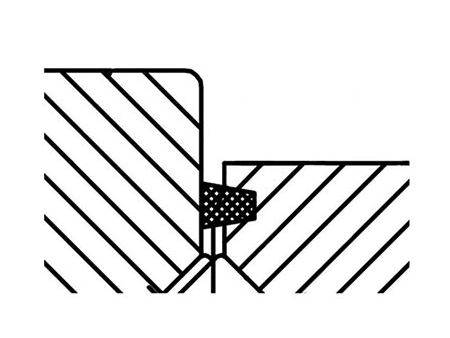

Work piece: bearing bore, end face

Material: Gr15

Hardness: HRC 55-62

Process: dry cutting

Original cutting tool: European PCBN cutting tools

Current cutting tool: Funik's FBS9500 CNGA120408

Efficiency comparison: same efficiency

Life comparison: upgrade from 30 pieces/edge to 50 piece /edge

About the Customer

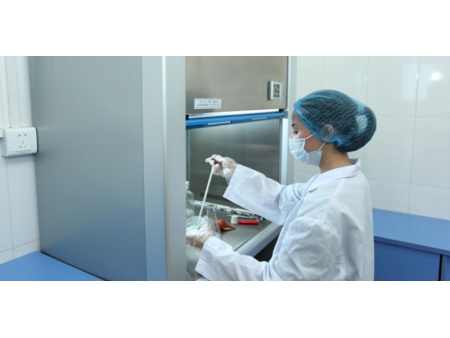

This customer is a bearing manufacturer located in Cixi, China. Hardened bearings have an extremely high hardness, making them difficult to machine using ordinary cutting tools. The question became how to improve processing efficiency while reducing costs. Using imported CBN tools, the processing effect is improved, but as they are generally expensive, many companies opt not to go that route.

Expert Review

From 2007, depending on the long-existing CBN powder business, Funik has developed various CBN cutting tools and has continued to make breakthroughs in machining in different industries to solve a variety of conventional processing problems. Funk helps enable the turning method instead of grinding, which improves the production efficiency and reduces costs.