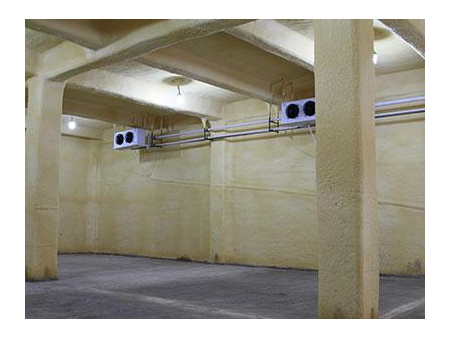

Insulated Wall Panels & Floor Panels

There are two primary thermal insulation processes: polyurethane foam spraying (thermal insulation material is directly sprayed onto the wall) and the other is a polyurethane cold storage insulation board (the standard insulation method).

Both insulation processes block all outdoor heat and retain the indoor cooling capacity in order to protect the cool air inside and reduce loss. We traditionally use a high quality polyurethane cold storage insulation board for prefabricated cold storage.

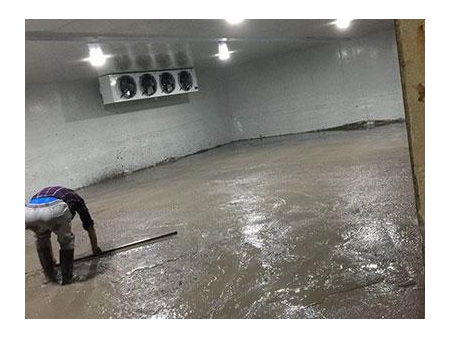

- Spraying thermal insulation materials on site

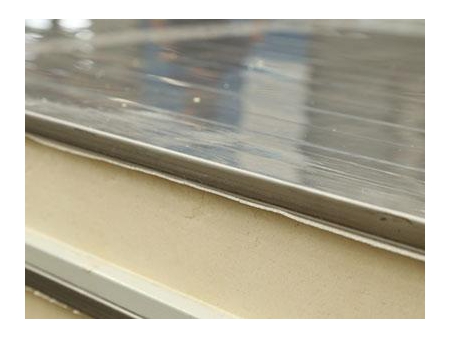

Stainless steel insulation board

Stainless steel insulation board Color steel insulation board

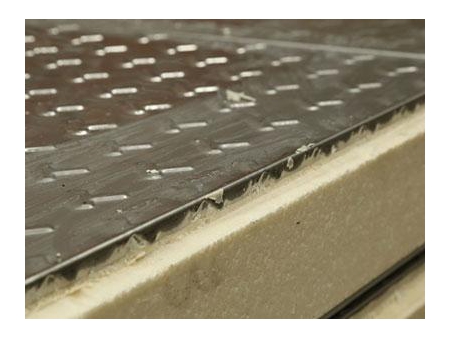

Color steel insulation board Anti-skidding stainless steel insulation board

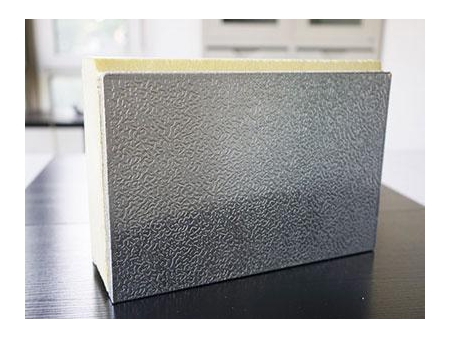

Anti-skidding stainless steel insulation board Insulation board with embossed aluminum cladding

Insulation board with embossed aluminum cladding

| Thickness of steel plate | 0.4-1.5mm |

| Galvanizing process | Hot galvanized, cold galvanized |

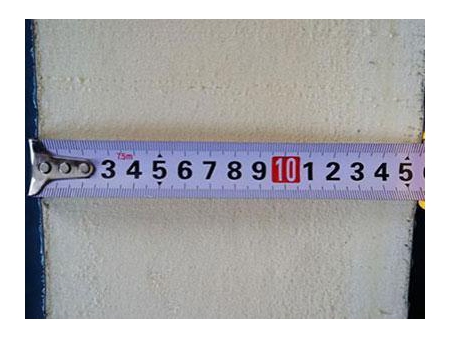

| Thickness of polyurethane board | 100/150/200mm |

| Polyurethane width | 960-1000mm |

| Thermal Conductivity | 0.019kal/mh℃ |

| Average density | 40-50K/O |

| Compressive strength | ≥0.2MPa |

| Maximum operating temperature | 90℃ |

| Minimum operating temperature | -120℃ |

| Fire-proof level | B1,B2 |

200mm insulation board

200mm insulation board 150mm insulation board

150mm insulation board 100mm insulation board

100mm insulation board

XPS extrusion board is the traditional material used in cold storage ground insulation. This material is lightweight and environmentally friendly, featuring a closed pore honeycomb structure. Not only does it have an excellent thermal conductivity, but it features an excellent pressure resistance, aging resistance, hydrophobicity and moisture resistance, thus satisfying comprehensive cold storage insulation requirements.

XPS extrusion board

Concrete floor

low cost, but easily produces powder

Emery floor

excellent abrasion resistance, durability and low cost. Less powder produced.

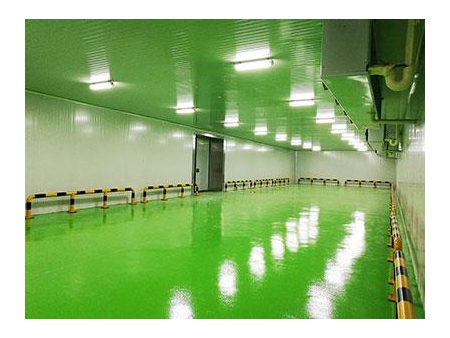

Cured floor

A penetrant and curing agent are added to emery. It has a longer service life and does not crack easily. It has a glossy surface.

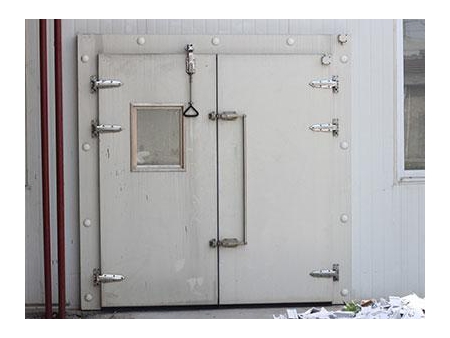

The cold storage door board can be made of stainless steel or colored steel according to requirements. Hard polyurethane foam materials are inserted between two door layers in order to ensure a smooth appearance and excellent thermal insulation.

The door is 4x4 m, with customers able to choose the structure and style based on their needs. A hinged door is suitable for small scale cold storage rooms that do not require the use of a forklift and will store only a small amount of goods. An electric vertical lift door is suitable for larger applications. As an example, an electric vertical lift door is often used in unloading platforms. Listed below are common cold storage door types.

Automatic double leaf sliding door

Automatic double leaf sliding door Electric vertical lift door

Electric vertical lift door Electric vertical lift and double leaf sliding door

Electric vertical lift and double leaf sliding door Manual double leaf sliding door

Manual double leaf sliding door Manual one leaf sliding door

Manual one leaf sliding door Hinged one leaf door

Hinged one leaf door Hinged double leaf door

Hinged double leaf door Self-closing door

Self-closing door