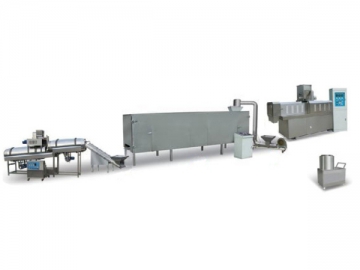

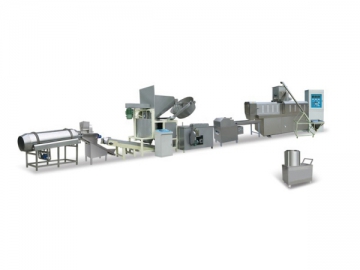

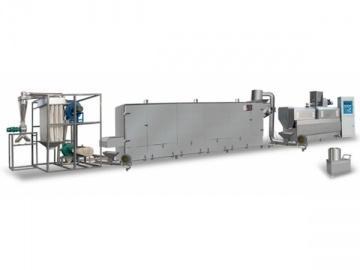

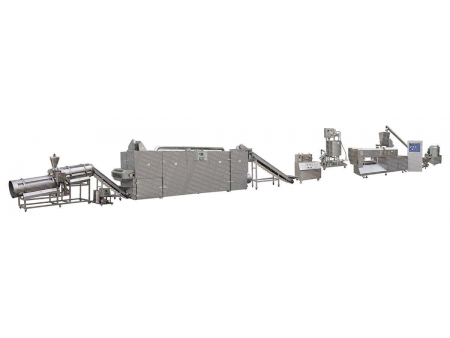

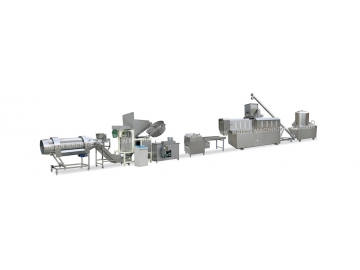

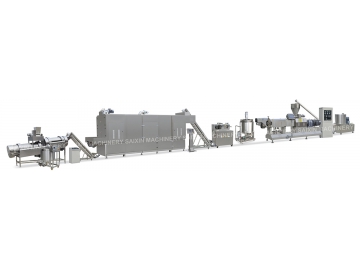

Puffed Snack Food Processing Line

We offer puffed snack food processing line in various models, configurations, and sizes. At the heart of this snack processing line is the twin-screw extruder where the pre-mixed extrudate is cooked, plasticized, sheared and pushed through the holes of the die at the end of the extruder barrel.

The die is simply a perforated plate with holes that allow hot extrudate to pass through. By swapping in and out different dies and retrofitting the existing food production facility, users can extrude new snacks to keep up with the market trend. Crunchy, easily digestible snacks including breakfast cereals, cream filled products, and modified starches are ideal choices for many young people.

High-precision control cabinet allows for easy, automated operations, as each puffed snack food processing line only requires 1 to 2 workers.

Food Extrusion Process Flow

1.

Different mixer models should be used depending on the target productivity on the puffed snack food processing line.

2. Auger Conveyor

The auger conveyor takes the mix to the extruder all the while carrying out a secondary mixing operation.

3.

The choice of twin-screw extruders should be based on the target production rate of the food processing line. Typically working in a speed range from 100kg/h to 500kg/h, the twin-screw extruder can handle cornmeal, rice flour, wheat flour, barley four, and other grain products.

4. Pneumatic Conveying Blower or Bucket Elevator

By using a blower or bucket elevator, semi-finished snacks are raised to a higher position where the drying oven is placed.

5.

Most of our multi-tier ovens are electrically powered, delivering a temperature range up to 200°C. Via operating the control cabinet, operators can freely set the drying temperature and time. Inside the oven are stainless steel wire meshes and bags.

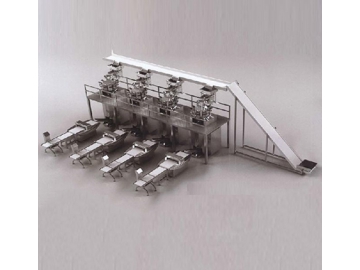

6. Vibratory Screening (Optional)

This process removes scraps, crumbs, crusts and unqualified snacks.

| Model | Installed Power | Power Consumption | Main Motor Power | Output Capacity | Installed Dimensions |

| 35KW | 22-30KW | 22KW | 100-200KG | 15×2.5×4M | |

| 45KW | 30-35KW | 30KW | 150-300KG | 16×2.5×4M | |

| 55KW | 35-40KW | 37KW | 300-500KG | 27×2.5×4.5M |