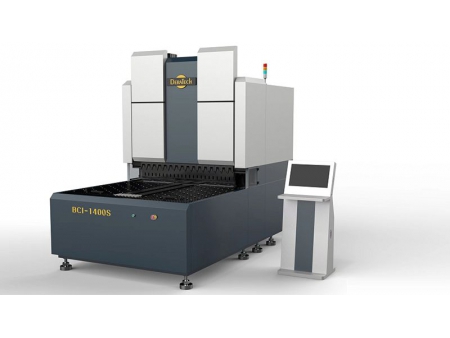

Bending Center with Suction Cup

BCI Series

BCI Series

Deratech launched BCI series bending center with a suction cup is an excellent solution for thin sheet metal bending. Featuring full servo control, a short stroke, and rapid feeding, this machine can complete a single bending operation in as fast as 0.2 seconds. Moreover, its one-time loading capability enables the entire bending process of the sheet metal to be completed seamlessly. When combined with the flexible bending loading and unloading unit, it delivers automatic production.

- Electronic components manufacturing

- Electrical metaleEnclosures fabrication

- Sheet metal fabrication

| Model | ||

| Max. bending size (mm) | 1400×1400 mm | |

| Min. double side forming size | 140 mm | |

| Min. four side forming size | 140×210 mm | |

| Max. bending height | 170 mm | |

| Max. panel thickness | Carbon steel panel (UTS 410 N/mm2) | 1.2 mm |

| 304 stainless steel panel (UTS 515 N/mm2) | 1 mm | |

| 201 stainless steel panel (UTS 520 N/mm2) | 0.8 mm | |

| Aluminum panel (UTS 265 N/mm2) | 1.6 mm | |

| Min. panel thickness | 0.35 mm | |

| Peak power | 34 kW | |

| Average power | 1.5 kW | |

| Bending angle | ±150° | |

| Servo axis | 9 PCS | |

| Dimensions(L*W*H) | 3660×1910×2900 mm | |

| Machine weight | 10 Ton | |

- Scientific structural design

The entire process is computer-aided, including design and validation. The equipment's core framework is built using high-grade castings such as QT500-7, HT250 and above, which ensure strong stability.

- Precision drive mechanism

The drive mechanism adopts heavy-duty ground ball screws, with a maximum specification of 8020. Theses ball screws are coupled with heavy-duty type high-precision P3 grade 55 roller type linear guides.

- Quick-release tools

Equipped with precision standardized bending and press tools, the surface hardness achieves over HRC55. The tools are convenient to disassemble and can be customized according to customer requirements.

- Precise and stable positioning system

The machine adopts the Y-axis three-point positioning method for material feeding, along with the use of suction cups to securely hold the workpiece in place.

- Sheet Thickness Measuring Device