Lithium Chloride Drying System

Industrial Drying Solutions

We provide industrial drying solutions for the moisture control of lithium chloride (LiCl) after a centrifugal separation process

Drying Conditions and Considerations for LiCl

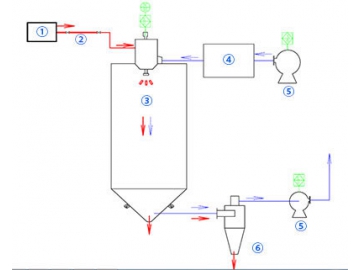

Drying lithium chloride comes with a few challenges, mainly due to its high solubility in water and its tendency to form crusts during the process. These factors make it harder for moisture to be removed through conventional drying methods. Once anhydrous lithium chloride is separated by centrifuge, a screw feeder delivers the material in a controlled and continuous flow into a rotary tray dryer designed for efficient thermal processing. As the material moves through the trays, heat and mass transfer occur simultaneously, allowing the product to dry gradually and evenly.

Once the target moisture level is reached, the dried material is cooled to packaging temperature, typically around 40–60°C, within the same unit. It is then discharged through a bottom outlet and transferred to the packaging section. Exhaust air containing residual moisture is vented through the top of the dryer and passes through a dust removal system before being released.

- The lithium chloride drying system runs continuously and maintains thermal efficiency above 85%, making it suitable for stable, large-scale production.

- More than 99.9% of powder can be recovered during operation, helping to reduce material loss and keep the work environment clean.

- Special rotating arms are used to prevent the material from sticking to the drying trays, keeping the process smooth and consistent.

- Each tray can be set to heat or cool independently. This allows drying and cooling to happen in the same unit, with better control over the product temperature.

- A built-in crushing device is added inside the dryer to break small clumps into powder, which improves heat transfer and makes the final product more uniform.

- Since lithium chloride has a high boiling point at normal pressure, the drying system uses high-temperature thermal oil to speed up the drying process, usually completed in about 30 minutes, while also reducing equipment costs.

- Three different types of titanium are used in the dryer structure to resist chloride corrosion, ensure long-term durability, and keep the equipment design practical and cost-efficient.