Product Strength

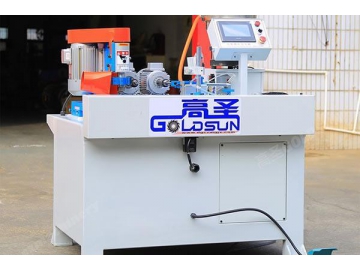

Our hot-sale products include CNC mortising machine, double-end tenoning machine, automatic chamfering, drilling and tapping machine, automatic chair back drilling and tapping machine and so forth.

Main advantages of our woodworking machines are shown as follows- All our products possess stable properties, high efficiency and simple operation system. Users don't need to consult the instruction manual to operate our furniture making machines, time saving and highly cost efficient.

- The operation method is very easy and one operator can operate several machines at the same time, which saves a lot of labor and time cost.

- Well deigned, the machine has a medium size and compact design, with small occupation area and realizing optimal space utilization.

- Functions and programs are complete and not complicated, fully meeting the actual manufacture demands of customer.

- We perform strict quality inspection on each configuration mounted on our timber processing equipment, which repays us optimum quality, high reputation and sound sales.

In the below content, we will specifically introduce the working efficiency and outstanding advantages of our three flagship products. If you want to know more about our woodworking systems, please go to the product page.

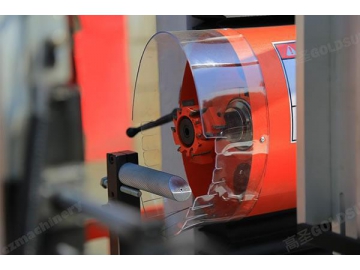

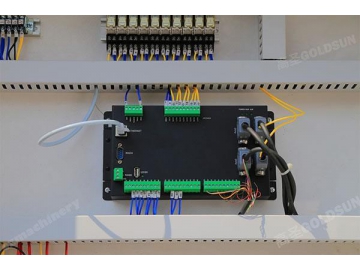

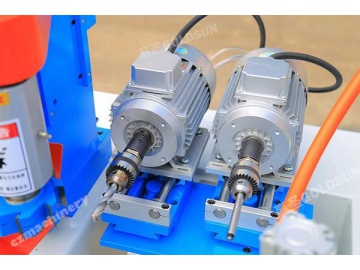

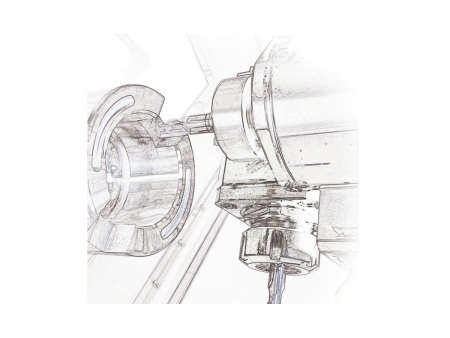

The first type of widely-used machine is CNC mortising machine. In comparison to conventional mortisers, our machine stands out for easy operation, fast adjustment, high efficiency, labor saving, medium volume and space saving. According to different working requirements, the CNC mortising equipment provides different efficiency and has various models. The mortising machine is equipped with HUST control system and Delta servo motor and has left and right processing area, realizing an efficiency of 16 pieces per minute and able to produce 7,000 prices in eight hours. As for machine debugging and adjustment, it is simply easy and requires no drawing. One machine demands only one operator. All the operator needs to do is to feed the raw material to the process zone, press down buttons and discharge the finished products.

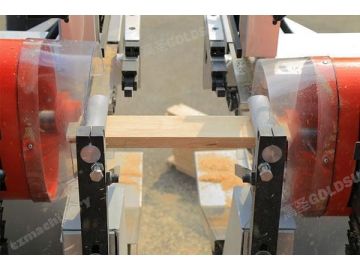

As for the double-end tenoning machine, it provides smooth and convenient operation, complete functions as well as automatic feeding and discharging. The tenoning machine accomplishes the process of 8-10 workpieces in one minute and 3,400 workpieces in eight hours.

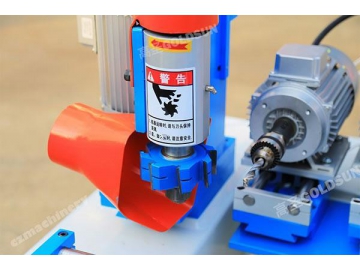

The third hot-sale product is automatic chamfering, drilling and tapping machine which does the double-cutting, drilling and tapping continuously. Its vibration disk automatically sends the material for tapping while the worker only needs to feed materials and discharge products. The wood process machine handles 5-6 workpieces in one minute and 2,000 workpieces in eight hours, greatly saving the production time and cost.