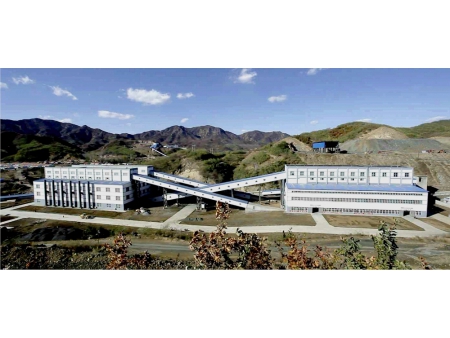

Project Management Capacity

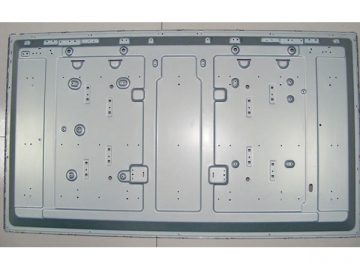

Based on forty years' development, Hisense Mold has become a capable mold supplier that can provide with customers a comprehensive set of services upon customers' requirements. Meanwhile, we can handle larger molds orders in an efficient way, providing quality custom molds, such as injection molds and sheet metal stamping dies, in possibly shortest time.

Stronger Capacity: with over 1300 sets of advanced equipment for mold designing and manufacture, we have strong production capacity to satisfy customers demands;

Professional Team: we have talented service teams who have good language skills, such as English, Japanese and Korean. Besides, our resource team and order executive team also help customers throughout the cooperation;

Rich Experience: we have rich experience in mould design and manufacture as well as service providing.

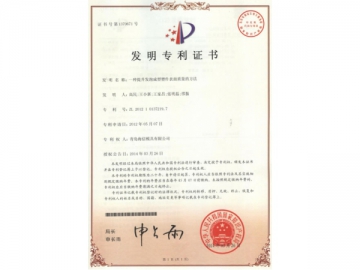

High R&D Capacity: supported by advanced research facilities as well as talented R&D teams, we have high researching ability, therefore able to provide custom mould solution you need as well as thorough services;

Systematic Organization System: carrying out divisional system,more professional service.

Efficient Management of Product Flow Path: with this efficient manage, we can significantly shorten the leading time and provide with customers all-around service.

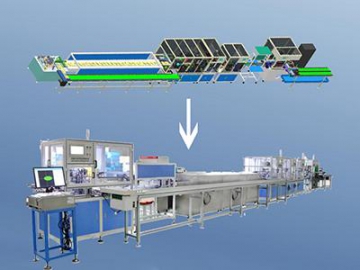

One-Stop Service

Product design(ID/MD) >> Mould design (CAD/CAE) >> Mould manufacturing (CAM) >> Mould polishing >> Mould assembly >> Trial Production >> Product Inspection & Delivery >> After-sale Service

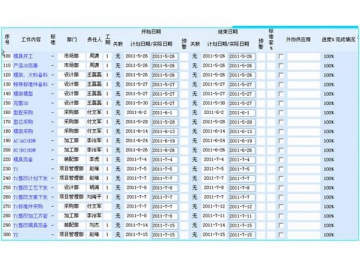

Precise Control Over Production and Leading Time

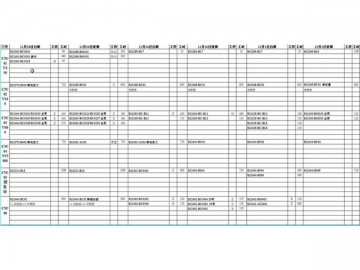

In 2006, we introduced the ERP system in hope of establishing a professional and efficient management and control system for leading time. Each link from the order confirmation to the final delivery will be well controlled and monitored according to the detailed plans we've made. These plans include a project plan, development implementation plan, the equipment plan, rolling plan of each three days, assembly plan, testing plan, improvement plan, multi-node plan, etc. It is in this methodical way that we satisfy our customers' request for leading time.

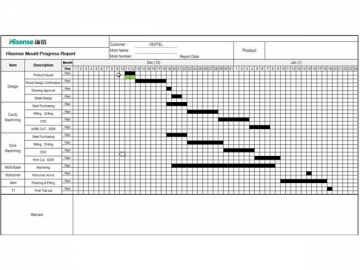

- Project Plan

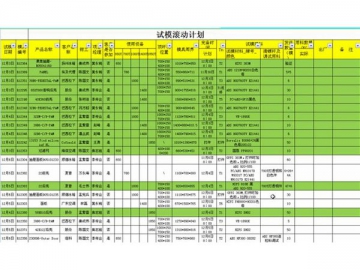

- Rolling Plan of Each Three Days

- Testing Plan

- Mold Production Schedule