Sheet Metal Parts

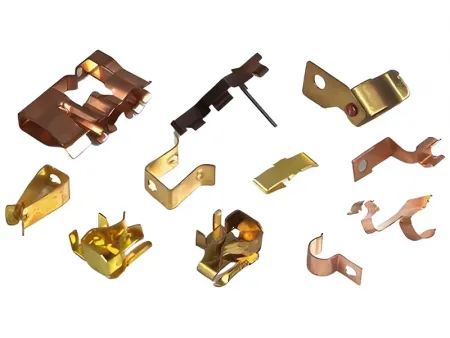

Sheet metal components are thin sheet metal parts formed by manually or die-based stamping processes that create precise shapes and dimensions through plastic deformation. These parts can be further refined through welding or machining to produce more complex assemblies.

Offering a unique combination of lightweight structure, high strength, electrical conductivity (ideal for EMI shielding), and cost-efficiency, sheet metal parts are exceptionally well-suited for high-volume production with consistent quality and performance.

With deep industry expertise, our skilled team manufactures precision sheet metal parts from a wide range of materials, including steel, aluminum, and stainless steel. Supported by comprehensive in-house capabilities and an uncompromising commitment to quality, we ensure reliable results for diverse industries, including automotive, electronics, home appliances, industrial equipment, and medical devices.

- Applicable Materials: Q235、SUS304

- Thickness: 0.3-5mm

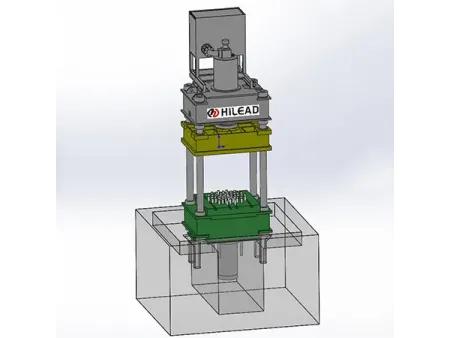

- Equipment Used: Shearing Machine, bending machine, stamping press

- Secondary Processing: Die forming, punching, bending

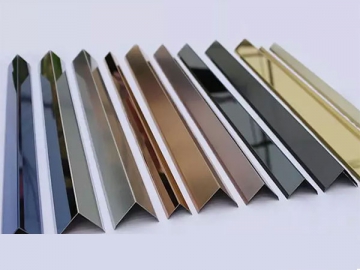

- Surface Treatment: Electroplating, polishing

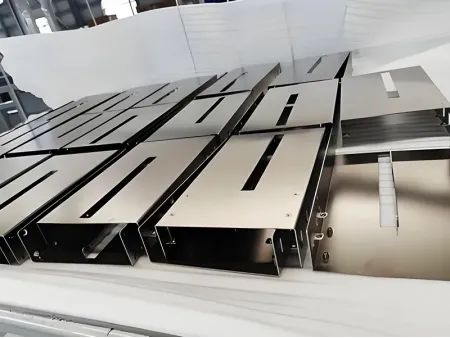

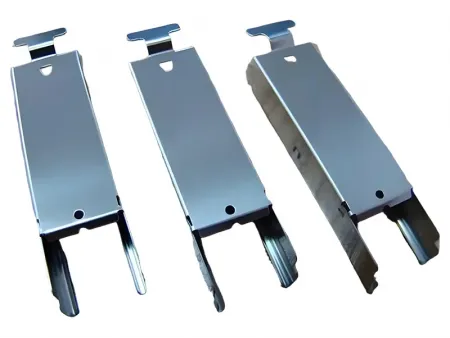

SFP housing SUS304

SFP housing SUS304 Automotive mudguard SUS304

Automotive mudguard SUS304 Automotive component SUS304

Automotive component SUS304 Distribution box SUS304

Distribution box SUS304 Distribution box SUS304

Distribution box SUS304 Motor housing SUS304

Motor housing SUS304 Generator housing SUS304

Generator housing SUS304 Lock metal component SUS304

Lock metal component SUS304

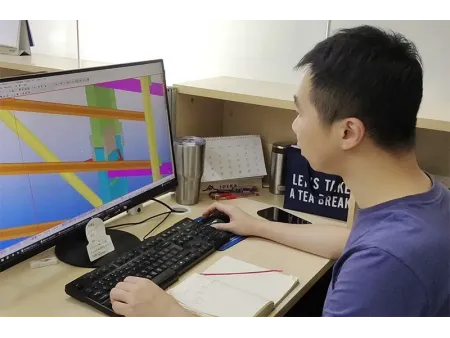

We provide comprehensive sheet metal solutions that integrate product design, engineering, rapid prototyping, and full-scale production. Leveraging advanced technologies, we serve a wide range of industries including aerospace, defense, automotive, energy, medical, dental, and more.

Laser cutting uses a high-powered laser beam to precisely cut metal sheets. Compared to traditional methods, it offers superior precision, the ability to create complex geometries, and minimal material waste.

Bending is a critical process in sheet metal fabrication. The inside bend radius should be at least equal to the material thickness, and all bend angles should be held within a tolerance of ±1 degree to ensure accuracy.

Our project managers carefully review customer drawings and specifications to ensure all requirements are met. Controlled procedures, routing documents, and inspection plans are used to translate customer expectations into clear manufacturing instructions. Each production step follows defined processes and inspection protocols to guarantee strict compliance with quality standards and client expectations.