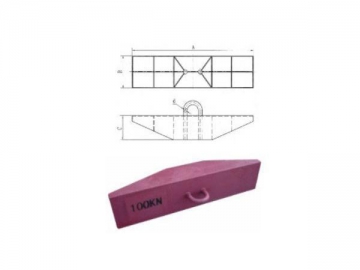

Temporary Strand Anchor

Year: 2017-2018

Anchor used: Temporary Strand Anchor

Project Overview

The foundation pit support project was carried out in Section 3, Jianshe North Road, Chenghua District. It is designed and constructed by Chengdu Surveying Geotechnical Research Institute Co., Ltd. Of MCC whereas Suzhou NG Foundation Engineering Co., Ltd. supplied hot-melt removable anchor products and technologies. The project involved 20 anchor, average 5 strands each, and has length 21 meters long each strand.

1. Construction stage

1 ). Inspected a total of 100 steel strands from 20 groups of anchors to ensure their electrical conductivity before construction.

2 ). After construction, randomly selected 10 anchors due to their working face. All strands were energized normally.

3 ). Tensioned hot-melt removable anchor lock time: 2017.11.23—2017.11.25

After the tension was locked, 10 anchors were sampled and all were energized normally.

2. Removing stage

Hot-melt removable anchor construction period: 2018.04.24 - 2018.05.03

1 ). Inspection was made on each strand before the anchor was removed. As a result, an anchor was found to be seriously damaged. We analyzed it and found out that the strand was damaged when the region around the reserved horse track was excavated. Each of the remaining three anchors had a strand energized abnormally, and the rest are normally energized and removed. The removing process was done by fully automated machine, which is safe and fast.

2 ). Regarded the damaged strand mentioned previously, we removed the clamp and cut off the out-spreading exposed steel strand. Next, we discovered that the conducting wire at the base plate are normally energized and hence we removed it through energizing.

3 ). The recovery rate reached 97% after the damaged steel strand was removed. Next, test was conducted to find out the location of the power cuts of the three strands that mentioned previously. It was found that one of the wires was broken at the position behind the pile. However, we were able to find out the intact wire after breaking the two piles at the middle. Later, removal of the anchors was made via energizing.

4 ). At this stage, the recovery rate had reached 98%. The broken wire was located deep in the anchor hole and hence it was difficult to remove it using normal energizing method. Thus, the two steel strands can be removed by remedy scheme.

- Carry out inspection before construction to ensure all anchors have normal electrical conduction.

- Conduct the test again after construction, if the anchor cannot be energized, remove the anchor rod before the concrete is solidify and reconstruct again.

- Inspect the anchor for its electrical conductivity. Remedy scheme can be made beforehand for anchors that fail to energized. The first method is to implement the casing drilling method to obtain the core before main structure is constructed; the second method is to carry out the casing drilling to obtain the core and pull out the anchor through the external wall of the basement after the main structure is constructed. The holes left in the casing after the drilling can be filled with foam concrete.

- The management department rejects the use of anchor if the recovery rate fails to reach 100%. Thus, for the purpose of bracing, it is strongly recommended that the use of high quality hot melt removable anchor which allows judgement of its energizing status and location of power cut beforehand instead of tens or millions of dollars spent for remediation and recovery. As such, remedy scheme can be conducted before the building was constructed to remove the anchor. As long as the construction unit is committed and responsible, it is technically 100% recoverable.

- Tension-locked anchor

- Anchor energizing test

- Removal and recovery of anchor

- Removal and recovery of anchor

- Acceptance of removed anchor

- Acceptance of removed anchor