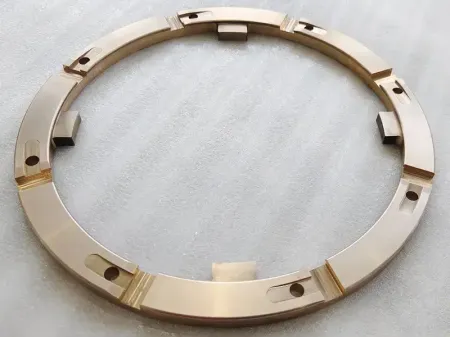

Bronze Rings

-

Maximum Outer Diameter up to 4000 mm

-

Maximum Weight of a Single Piece 5 tons

Bronze rings are wear-resistant copper alloy components generally used in industrial equipment to provide sealing and protection. They help prevent liquids or gases from leaking between connected parts of a system and are chosen for their durability and corrosion resistance. In some cases, the bronze rings are made with an open or split design to make installation and removal easier during maintenance.

Each bronze ring is made using high-purity metal elements (99.99%) and cast through advanced centrifugal casting processes. The bronze blanks are stored and traceable for up to five years, or longer if required, to ensure consistent material quality. To ensure the bronze rings efficiency and durability, precision machining is carried out on five-axis CNC machines, with each production step completed under ISO9001 and CCS requirements. The finished bronze rings are then tested in our CNAS-certified lab to make sure their dimensions and quality meet the required standards.

| Material No. | | | |

| Category | High-Leaded Tin Bronze Alloy | Aluminum Bronze Alloy | High Iron Bronze |

| Core Properties | • Low friction coefficient • Strong anti-seizing ability • Excellent machinability and good castability | • High wear and impact resistance • Strong corrosion resistance • Tensile strength 600–750 MPa, hardness HB 170–220 | • High wear and corrosion resistance • Stable strength at high temperatures (below 300°C) • Good bonding strength |

| Typical Applications | Used for small and medium-sized bearings, machine tool bushings, pump impellers, and hydraulic components. | Suitable for large bearing parts, main shafts, valve components, marine hardware, and high-pressure bases. | Commonly used for sliding blocks, high-temperature bearing parts, internal combustion engines, and heavy-duty mechanical guides. |

Bronze wear rings have different roles depending on the type of equipment they’re used in:

- Motors: act as collector rings that provide smooth electrical contact and better conductivity than steel ones.

- Wind turbine gearboxes: use tin bronze rings because the material casts evenly and maintains its shape, which is suitable for producing detailed or complex parts.

- Hydropower turbines: use bronze sealing rings to stop water from leaking and keep the system running smoothly and efficiently.

- R&D Capability

We handle every production stage independently, from the development and casting of bronze wear parts to machining and quality inspection. This allows us to have full control over product quality and ensures that each process is backed by our proprietary know-how and patented technologies.

- Industry Experience

Backed by more than 40 years of experience, we specialize in bronze wear parts for wind power, mining, hydropower, marine, and oil extraction equipment. Our product catalog includes bronze and steel bearings, bushings, and other wear components. We have long-term partnerships with several Fortune 500 companies within these industries.

- Production Strength

Our workshop is equipped with 20 advanced five-axis machining centers from MAZAK and MAKINO, along with 35 imported turning and milling machines. The 5,000 m² temperature-controlled facility is operated by experienced CNC technicians who make sure every part is machined with accuracy and consistency.

- Quality Control and Certifications

We manage every step of production in-house, following ISO9001 and CCS quality standards to ensure consistent results. Our CNAS-accredited laboratory (CNAS L5937) and skilled inspection team handle all testing and verification, including material composition, hardness, tensile strength, and microstructure, along with non-destructive tests such as UT, PT, and VT. All procedures comply with GB, ASTM, ISO, JIS, and YS standards.