Your trusted partner for bagging and palletizing systems

DT-YB-S-C

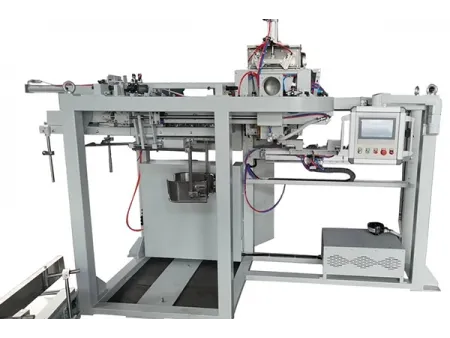

Open-mouth bagger for filling and closing pre-made open-mouth bags with granular or powder materials

500-600 bags/hour (single packaging line)Designed for filling and closing pre-made open-mouth bags, this semi-automatic system handles granular and powder materials across a wide range of production environments. The bagging machine combines automated functions with simple operator interaction, making it a practical choice for plants seeking higher efficiency without the investment of a fully automated line.

The open-mouth bagger consists of a bag-pickup device, a bag-clamping system, a bag-delivery trolley, an infeed module, a standing-bag conveyor, and an integrated control system. Together, these components streamline the manual bag-placement process and help maintain consistent output during continuous operation. This palletizing sytem is widely used in food, chemical, building materials, and feed production. It is especially suitable for medium-scale factories planning a gradual move toward automation. The system reduces manual workload and improves daily throughput, while avoiding the higher cost and maintenance demands associated with fully automatic equipment.

| Model | DT-YB-S-C |

| Capacity | 500–600bags/hr (single packaging line) |

| Control system | PLC control with independent touch-screen real-time monitoring (machine operation is not affected in case of touch-screen failure) |

| Machine main material | Carbon steel (other materials customizable upon request) |

| Filling weight | 40&50kg/bag (net weight) |

| Air consumption | Approx. 60m³/hr per unit |

| Power supply | AC 380V, 50Hz, approx. 20kW/unit |

Specifications are subject to change without prior notice.

Product images may differ from the actual model configuration.

This conveyor is equipped with a frequency-controlled geared motor. Its overall height is adjustable to ensure smooth bag transfer into the sewing system for synchronized stitching.

| Type | Continuous belt conveyor |

| Conveying speed | 15m/min (frequency adjustable) |

| Conveyor length | 3500mm (final length based on on-site requirements) |

| Belt width | 410mm |

| Power supply | Three-phase (3PH), AC 380V/50Hz |

| Total power | 1.5kW |

| Main material | Carbon steel |

| Servo motor | HCFA (adjustable per actual conditions and customer requirement) |

- The bag placer uses an adjustable-width gripper and an electrically driven height-adjustable standing conveyor, allowing bag changes to be completed in under two minutes.

- Filling and sealing are fully automated, requiring no manual intervention and supporting continuous production. It handles a wide range of bag types, including woven bags, PE bags, standard flat-top bags, and M-type gusset bags.

- Multiple closing configurations are available, such as folding with stitching, heat sealing, or a combination of inner-bag heat sealing followed by folding and stitching, giving users greater flexibility for different packaging requirements.

If you have questions or need further information, our team is here to assist you, feel free to contact us.