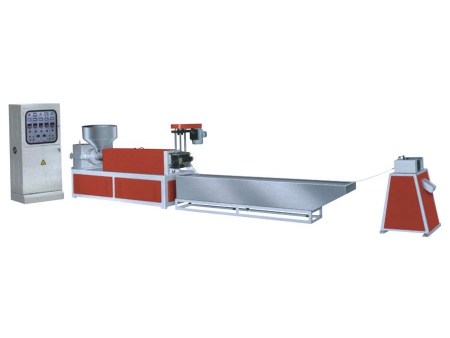

Single Screw Extruder

Plastic Extruder, Extruding Machine for Plastic, Plastic Sheet Extruder, Plastic Pellet Making Machine

Different Kinds of Single-Screw Plastic ExtrudersZ-SJ Series Single Screw Extruder

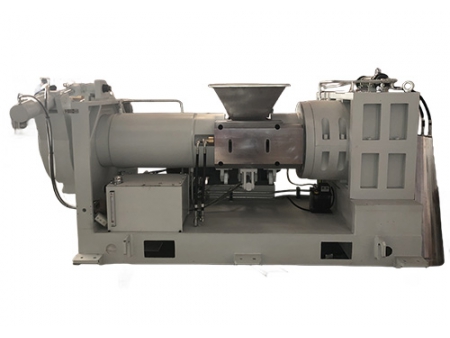

Z-SJ series single screw extruder is applicable in processing pipes, plates, sheets, rods, profiles and plastic pellets made from PP, PE, PS, ABS, PMMA, PVC and other thermoplastic materials. The aspect ratio and compression ratio of screw, and the structure of machine barrel varies according to different materials and product specifications to meet diversified processing requirements. To meet high-quality processing needs, operators can choose the appropriate barrels, screws, and driving system.

This kind of extrusion machine adopts frequency control and speed reducer. It features low noise, stable running, large bearing capacity and long service life. Upon clients’ request, computer control or conventional control system is available.

Technical Parameters| Model | ||||||

| Aspect ratio (L/D) | 25-33/1 | 25-33/1 | 25-33/1 | 25-33/1 | 25-33/1 | 25-33/1 |

| Extrusion capacity (kg/h) | 50-150 | 60-250 | 200-350 | 180-550 | 320-800 | 400-1200 |

| Screw Speed (r/min) | 20-150 | 20-150 | 20-150 | 20-110 | 20-90 | 20-75 |

| Motor power (kw) | 7.5-22 | 22-90 | 55-110 | 37-185 | 75-280 | 90-355 |

| Central height (mm) | 1000 | 1000 | 1000 | 1000-1100 | 1000-1250 | 1000-1300 |

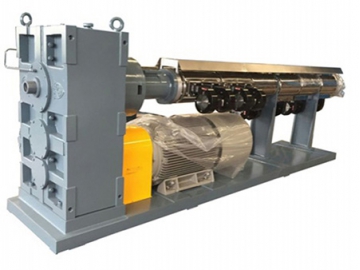

HDPE High-Speed Single Screw Extruder

High speed high-efficiency single-screw extruder is designed for different materials and product specifications. Aspect ratio and compression ratio of the screw, as well as structures for the machine barrel can be different to meet different processing requirements. Users can choose the appropriate barrel, screw and driving system on the basis of their needs.

In the extrusion process of the HDPE single screw extrusion machine, plasticizing and mixing is conducted uniformly, and materials are not easy to get broken. This extruder appears high output and stable performance. It is especially suitable for extruding PE plastic pellets. We have equipped it with a cooling device for the barrel, and an auto temperature control system. DC motor and variable frequency control is employed for the main motor. The HDPE plastic extruder features simple structure and convenient maintenance. The detailed settings can be adjusted upon clients’ demands.

Technical Parameters| Model | |||||

| Aspect ratio(L/D ) | 33/1 | 33/1 | 33/1 | 33/1 | 33/1 |

| Production capacity (kg/h) | 60-250 | 200-350 | 180-500 | 320-800 | 400-1100 |

| Screw speed (r/min) | 20-150 | 20-150 | 20-120 | 20-90 | 20-75 |

| Motor power (kw) | 75kw | 110kw | 160kw | 250kw | 315kw |

| Central height (mm) | 1000 | 1000 | 1000-1100 | 1100-1250 | 1100-1300 |

Vented Single-Screw Plastic Extruder

Vented single-screw plastic extruder is mainly used for processing polymer materials with high moisture absorption, such as rigid polyvinyl chloride, ABS, nylon, polyoxymethylene and polymethyl methacrylate. With good exhaust effect, the foam of the extruded materials is largely reduced, so the quality of finished products is greatly improved. We have developed vented extruder both for plastic pelletizing and profile processing.

Graphite Extruder

This kind of extruder is mainly used as conductive materials for rail transit like high-speed rail and subway.

1. Temperature Control System

The temperature controller from well-known brand can keep the temperature deviation at ±1℃.

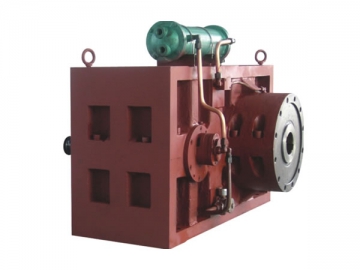

2. Gear Box

The hardened gears are distinguished for low noise, stable running, large bearing capacity, and long service life. High-torque gearbox is optional.

3. Screws

For the screws of extruder, a new screw structure is employed to ensure a uniform melting and mixing result, as well as a high output under low melting temperature. For the materials of screw, we have adopted nitriding treatment with 38CrMoAIA to achieve a high screw surface hardness. Either air or water cooling is available with the cast Aluminum /copper heater.

According to different raw materials and product specifications, the aspect ratio and compression ratio of screws is different. Screw barrels are available in various structures. It supports high precision, good plasticizing effect, and large output, and can basically meet clients of different groups.

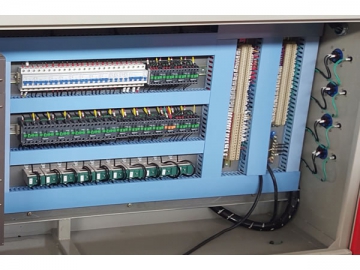

4. Electrical Control System

The single-screw plastic extruder is equipped with advanced electrical control and AC/DC stepless speed regulation system. All of the circuit layout and arrangement is conducted in accordance with CE- MD: 2006/42EC LVD: 2006/95/EC standards. Zeqi has established long-term partnerships with many well-known electrical component suppliers, like Siemens, ABB, Omron, Schneider, Chint, West Germany, Senlan, and so on, to ensure the life and security of our plastic extrusion machines.

Applications of Single-Screw Extruder

1. It is used for extruding plastic pipes, plastic profiles, plastic sheets, plastic bars, and plastic pellets from thermoplastic materials like PP, PE, PS, ABS, PMMA, and PVC, etc.

2. Plastic pipe extruding: PP-R pipe, PE gas pipe, PEX cross-linked pipe, aluminum-plastic composite pipe, ABS pipe, PVC pipe, HDPE silicon core pipe and a variety of co-extruded composite pipe

3. Plastic sheet and plate extruding: PVC, PET, PS, PP, and PC materials, etc.

4. Plastic profile extruding: users can utilize the extruder to produce PVC and Polyolefins plastic profiles by adjusting the speed of the extruder or structure of the screw

5. Plastic modification and pelletizing: applicable in mixing, modifying, and pelletizing of various plastic