Automatic Dupont Wire Crimping and Housing Insertion Machine

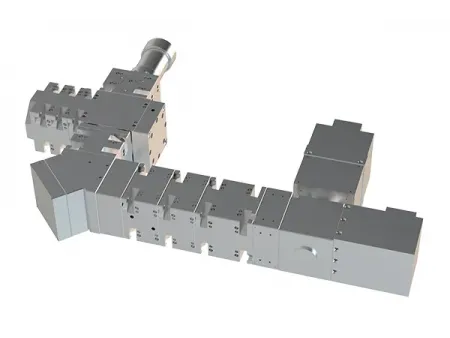

Cable assembly processes require precision and efficiency, especially when handling diverse wire configurations. Our Dupont wire crimping & housing insertion machine integrates multiple wire processing operations, including cutting, stripping, 2-sided crimping, and single-sided seal or housing insertion, into one system. This model of wire terminating machine is designed to handle a variety of wire types, including PVC, silicone, Teflon-coated, and halogen-free options, it supports various spacing configurations including 0.8, 1.0, 1.25, 1.5, 2.0, 2.54, 3.96. Its versatility ensures smooth transitions between different production needs, making it an efficient choice for complex manufacturing processes.

- 2-sided crimping and housing insertion: 8,000–12,000 terminals per hour.

- 2P ribbon cable (4m length) with bundling: 2,200–3,000 terminals per hour.

| General | Model | ||

|---|---|---|---|

| Dimensions (L×W×H) | 4000×3000×1800mm | 4000×1200×1800mm | |

| Weight | Approx. 1000kg | Approx. 600kg | |

| Power Supply | AC220V 50Hz | AC220V 50Hz | |

| Rated Current | 18A | 18A | |

| Power | Approx. 8kW | Approx. 6kW | |

| Air Pressure | 0.4-0.6Mpa (the air must be filtered and dried) | ||

| Space Requirement | 2.5×6.0m | 2.5×6.0m | |

| Crimping Force | 2T | 2T | |

| Functions | Housing | Pitch 1.0-VH3.96mm | |

| Crimping Capacity | 8000-12000 crimps/hr (two-sided housing insertion without tying), 2200-3000 crimps/hr for 2P ribbon cable of 4 meters (housing insertion with tying), (depending on cable material, length and number of pins) | ||

| Control System | PLC control, servo motor | ||

| Wire Processing | Two-sided crimping and housing insertion, Two-sided crimping one-sided housing insertion, One-sided crimping and housing insertion one-sided tinning, One-sided housing insertion and tying, Two-sided housing insertion and tying | One-sided crimping and housing insertion one-sided tinning, One-sided crimping one-sided tinning, One-sided housing insertion one-sided tinning and tying, One-sided housing insertion and tying | |

| Operation Control | Wire feeding, cutting, stripping and crimping are controlled via touch screen, with PLC full servo control One-key switching from two-sided housing insertion to one-sided housing insertion and tinning | ||

| Detection Devices | Crimp test, wire shortage detection, air pressure test, paper winding inspection | ||

| Auxiliary Equipment | Crimp terminal waste / wire strip waste collector, paper winder, air storage buffer tank | ||

| Optional | Pressure Measuring Device | Used to measure terminal crimping pressure | |

| Vision Inspection | Inspection of copper wire, crimp terminal, color, and terminal housing | ||

| Application Range | Cutting Length | 45-850mm (customizable) | |

| Stripping Length | Front: 1-8mm, Rear: 1-12mm | ||

| Wire & Cable Type | Ribbon cable (AWG28#-AWG18#) | ||

| Max. Wire Width | 45mm | ||

| Number of Pins | 1-5pin | ||

-

Equipped with intelligent touch screen controls to allow operators to adjust wire length, stripping depth, terminal crimping, and housing insertion with precision and ease.

-

Its robotic clamping ensures stable wire feeding and precise alignment, guaranteeing consistent results across all operations.

-

Supports 2-20P configurations with minimal accessory changes, offering flexibility for a range of production needs.

-

Built-in error detection displays real-time alerts on the touch screen, simplifying troubleshooting and enhancing productivity.