Polyester Meshes for Paper Machine

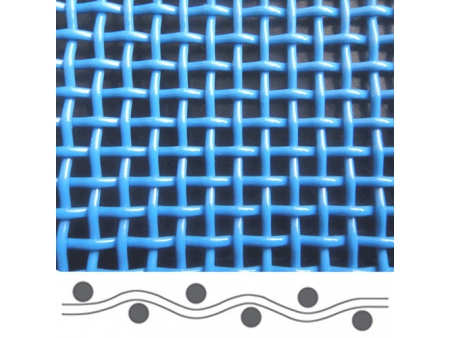

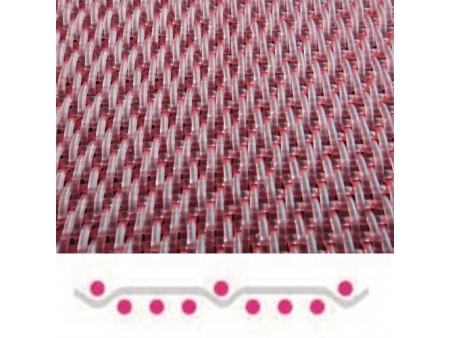

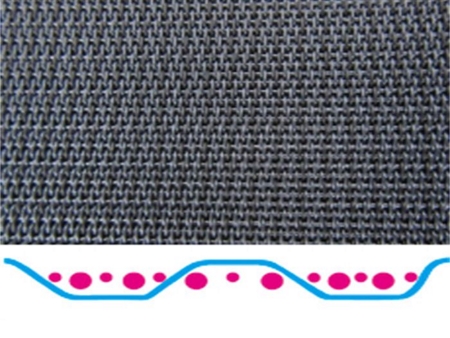

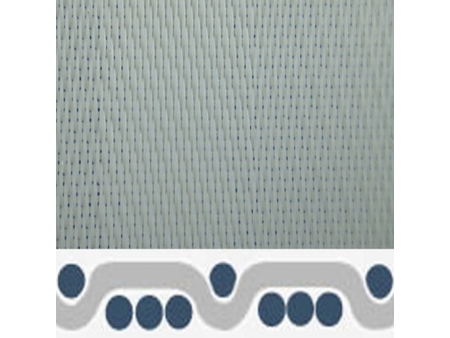

Huatao polyester plain woven fabirc, also known as polyester plain weave mesh conveyor belts in drying process, are generally woven in 2-shed or 3-shed polyester meshes. And they can be customized to meet different mesh, thickness, weight and air permeability requirements. Equally important, our polyester plain woven fabirc are used in artificial board plants. They are also widely applicable for material screening, drying, conveying and filtering, sludge and slurry dewatering, etc.

Specifications| Model | Thread diameter (mm) | Density (threads/cm) | Tensile strength (N/cm) | Weight (kg/ m²) | Thickness (mm) | Aperture size (mm) | Mesh count (warp×weft/inch) | Air permeability | Open area (%) | ||||

| Warp | Weft | Warp | Weft | Surface | Joint | m³/m²h | CFM (127pa) | ||||||

| 021002 | 1 | 1 | 2.85 | 2.85 | 1600 | 650 | 0.6 | 1.85 | 2.50×2.77 | 7.10×7.03 | 24656 | 1550 | 52.55 |

| 031002 | 1 | 1 | 3.2 | 3.25 | 1600 | 650 | 0.8 | 1.86 | 2.12×2.07 | 8.10×8.20 | 22251 | 1390 | 45.9 |

| 3902 | 0.9 | 0.9 | 3.9 | 3.65 | 1600 | 650 | 0.55 | 1.7 | 1.66×1.83 | 9.60×9.30 | 20000 | 1250 | 43.58 |

| 5602 | 0.6 | 0.6 | 5.9 | 5.6 | 1600 | 650 | 0.62 | 1.1 | 1.09×1.18 | 14.98×14.2 | 18000 | 1125 | 42.89 |

| 5802 | 0.8 | 0.8 | 5.1 | 5.3 | 1600 | 650 | 0.89 | 1.48 | 1.16×1.08 | 13×13.5 | 15840 | 990 | 34.09 |

| 6652 | 0.65 | 0.65 | 7.4 | 6.8 | 1600 | 650 | 0.65 | 1.19 | 0.70×0.82 | 18.8×17.3 | 14400 | 900 | 34.09 |

| 6802 | 0.8 | 0.8 | 6.6 | 6.5 | 1600 | 650 | 0.85 | 1.45 | 0.72×0.73 | 16.8×16.5 | 11600 | 725 | 22.65 |

| 06702 | 0.7 | 0.7 | 7 | 7 | 1600 | 650 | 0.77 | 1.3 | 0.72×0.72 | 17.8×17.8 | 11000 | 690 | 26.01 |

| 07802 | 0.8 | 0.8 | 7.8 | 7 | 1600 | 650 | 1.1 | 1.45 | 0.32×0.54 | 20.3×18 | 5920 | 370 | 16.54 |

| 9502 | 0.5 | 0.5 | 9.7 | 10.3 | 1600 | 650 | 0.5 | 0.9 | 0.53×0.47 | 25×26.2 | 10100 | 634 | 24.97 |

| 8603 | 0.5 | 0.6 | 9.4 | 9 | 1600 | 650 | 0.6 | 1.15 | 0.56×0.51 | 23.8×23.1 | 9000 | 560 | 24.38 |

| 9452 | 0.45 | 0.45 | 10 | 8.6 | 1600 | 650 | 0.45 | 0.88 | 0.55×0,71 | 25.4×21.8 | 15570 | 970 | 33.71 |

| 12502 | 0.5 | 0.5 | 13.5 | 8.5 | 1600 | 650 | 0.63 | 0.95 | 0.24×0.65 | 34.3×21.6 | 6500 | 282 | 18.68 |

| 6803 | 0.7 | 0.8 | 7 | 5.5 | 1600 | 650 | 0.75 | 1.53 | 0.72×1.0 | 17.8×14 | 16000 | 1000 | 28.56 |

| 7803 | 0.8 | 0.8 | 8 | 8 | 1600 | 650 | 1.15 | 1.66 | 0.45×0.45 | 20.3×20.3 | 9184 | 574 | 12.96 |

| 7903 | 0.9 | 0.9 | 7.6 | 6.5 | 1600 | 650 | 1.25 | 1.76 | 0.51×0.63 | 19.3×16.5 | 6400 | 400 | 16.26 |

- Precise opening and uniform aperture;

- Superior durability is available to extend its service life;

- Strong polyester fiber provides excellent stability and good abrasion resistance;

- High working temperature (-75°C to 150°C);

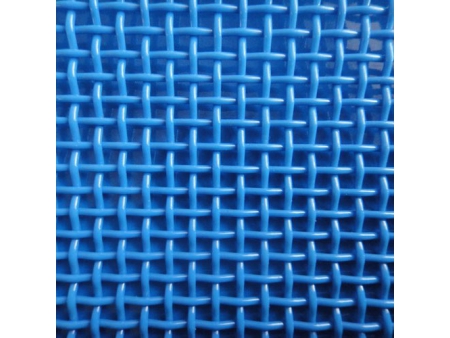

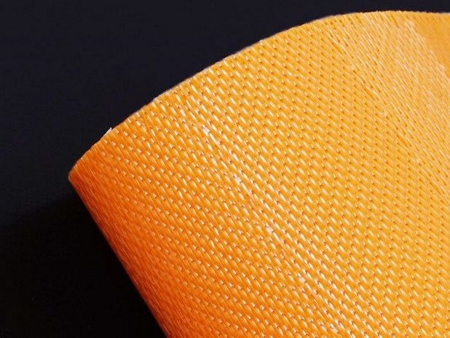

As a perfect engineering material in construction, the alkali- resistant mesh is featured by properties of high strength, good cohesion, and anti-alkali. It is mainly used in some industries that require high tensile strengths and outstanding performance of wear resistance.

Specifications| Model | Warp filament diameter (mm) | Weft filament diameter (mm) | Warp density (threads/cm) | Weft density (threads/cm) | Surface tensile strength (N/cm) | Joint tensile strength (N/cm) | Weight (kg/m²) | Thickness (mm) | Air permeability (CFM 127/pa) |

| 121104 | 0.90 | 1.1 | 12.8 | 4.0 | 1600 | 900 | 1.57 | 3.05 | 600 |

| 15905 | 0.90 | 0.90 | 15.3 | 5 | 1600 | 900 | 2.0 | 2.77 | 425 |

| 061204 | 1.20 | 1.20 | 7 | 4.3 | 1600 | 900 | 1.9 | 2.9 | 431 |

| 121201 | 1.05 | 1.20 | 12.6 | 7.4 | 1600 | 900 | 2.6 | 3.5 | 659 |

| 16903 | 0.70 | 0.90 | 16.3 | 5 | 1600 | 900 | 1.5 | 2.1 | 470 |

- High temperature resistance: It can continuously work at 100℃;

- Chemical resistance: Strong alkali resistance (such as 20% sodium hydroxide);

- Excellent tensile strength and high abrasion resistance: The abrasion resistance is 10 to 50 times of ordinary synthetic fiber;

- Smooth surface of this alkali-resistant mesh makes it easier to peel off from the loaded material;

- Stable dimension, high intensity;

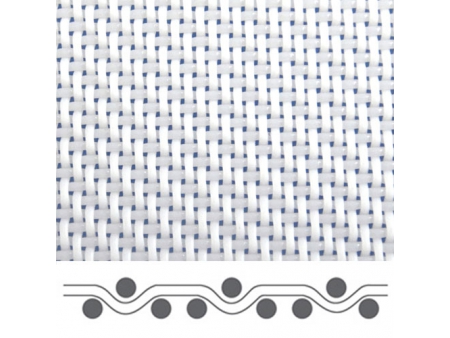

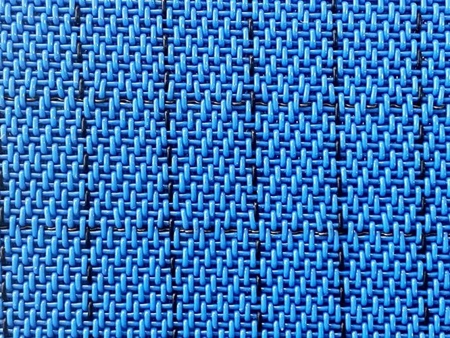

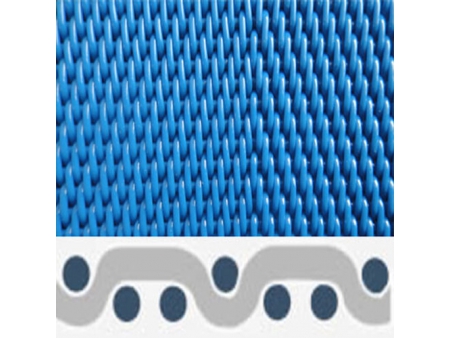

The anti-static mesh is generally made up of monofilament in spiral weaving. It is well suitable for use as continuous pre-press mesh belt in paper making and fiberboard production processes. Additionally, this anti-static mesh also has a wide range of applications in chemical fiber, rubber, environmental protection, and many other industries requiring conductive and anti-static properties.

Specifications| Model | Warp filament diameter (mm) | Weft filament diameter (mm) | Warp density (threads/cm) | Weft density (threads/cm) | Surface tensile strength (N/cm) | Joint tensile strength (N/cm) | Weight (kg/m²) | Thickness (mm) | CFM (127/Pa) | Electric conductivity (Ω×cm) |

| 31505 | 0.40 | 0.50 | 33 | 9 | 1600 | 900 | 0.80 | 1.30 | 186 | 5×10³ |

| 14804 | 0.65 | 0.80 | 14.8 | 7.2 | 2000 | 900 | 1.6 | 1.95 | 430 | 5×10³ |

| 14804-1 | 0.65 | 0.80 | 14.8 | 7.2 | 2000 | 900 | 1.6 | 1.95 | 430 | 5×10³ |

| 4106 | 0.50 | 0.30/0.70 | 22.8 | 2200 | 900 | 1.5 | 1.80 | 500 | 5×10³ | |

| 14708 | 0.64 | 0.70 | 15 | 8 | 2000 | 900 | 1.03 | 1.78 | 700 | 6×10³ |

| 12708 | 0.46×0.68 (flat yarn) | 0.70 | 14.1 | 7.3 | 2000 | 900 | 0.90 | 1.76 | 500 | 6×10³ |

- Good ventilation;

- Safe static discharge;

- Smooth surface;

- Easy for cleaning;

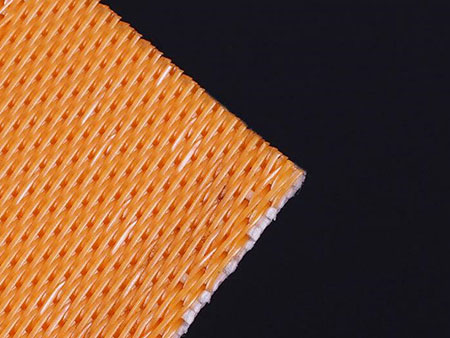

The desulfurization filter fabric is mainly used in some filters like rubber belt vacuum filter, horizontal vacuum belt filter, vacuum drum filter, vertical filter press and so on. In addition to wet desulfurization in power plant, it is also well suitable for tailings, metallurgy, mining, chemical, coal chemical, paper making, food, pharmaceutical and environmental protection industry and other specific industries requiring solid-liquid separation.

Specifications| Model | Warp filament diameter (mm) | Weft filament diameter (mm) | Warp density (threads/cm) | Weft density (threads/cm) | Surface tensile strength (N/cm) | Joint tensile strength (N/cm) | Weight (kg/m²) | Thickness (mm) | Air permeability (m³/m²h) |

| 27508 | 50×32 (flat yarn) | 6×0.18 0.50 | 28.5 | 25 | 2200 | 1000 | 1.2 | 1.95 | 1600 |

| 27508-1 | 50×32 (flat yarn) | 600D filament 0.50 | 28.5 | 21 | 2200 | 1000 | 0.90 | 1.90 | 720 |

| 27508-2 | 50×32 (flat yarn) | 600D filament 0.50 | 28.5 | 23.5 | 2200 | 1000 | 1.10 | 2.10 | 310 |

- The utilization of highly qualified polyester has greatly improved the abrasion resistance of desulfurization fabrics with smooth surface;

- Metal clip is made of 316L stainless steel, thus ensuring high resistance to strong acid and alkali corrosion;

- Smooth operation and not apt to corrugate;

- High filtration rate make it easier to peel off from the filter cake;

- With outstanding performances in filtration fields such as flue gas desulfurization and sludge dewatering industries;

- Can meet different filtration precision requirements (2-100μm);

- Excellent properties of abrasion resistance and acid and alkali corrosion resistance have greatly improved its service life;

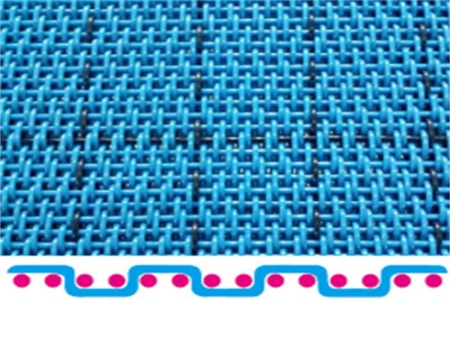

The quality sludge dewatering mesh is specially designed to dewater all sorts of sludge and slurry. With a wide range of applications in belt filter, rubber belt vacuum filter and horizontal vacuum belt filter, this polyester sludge dewatering mesh is widely used for the processing and treatment of sludge in our daily life and manufacturing plant, as well as juice concentrate press of food & beverage factories and other industries.

Specifications| Model | Warp filament diameter (mm) | Weft filament diameter (mm) | Warp density (threads/cm) | Weft density (threads/cm) | Surface tensile strength (N/cm) | Joint tensile strength (N/cm) | Weight (kg/m²) | Thickness (mm) | CFM (127/Pa) | Material |

| 121104 | 0.90 | 1.10 | 12.8 | 4.0 | 1600 | 900 | 1.57 | 3.05 | 600 | PA6 |

| 15905 | 0.90 | 0.90 | 15.3 | 5 | 1600 | 900 | 2.0 | 2.77 | 425 | PA6 |

| 061204 | 1.20 | 1.20 | 7 | 4.3 | 1600 | 900 | 1.9 | 2.9 | 431 | PA6 |

| 121204 | 1.05 | 1.20 | 12.6 | 7.4 | 1600 | 900 | 2.6 | 3.5 | 659 | PA6 |

| 16903 | 0.70 | 0.90 | 16.3 | 5 | 1600 | 900 | 1.5 | 2.1 | 470 | PA6 |

- The twill woven mesh is specially designed to achieve highly efficient filtration, smooth surface and easy mud cake removal;

- Quality polyester and nylon monofilament yarns make our woven mesh chemically resistant, thus ensuring outstanding mechanical stress and long service life;

- Customized services are provided in width of up to 8m and length of up to 200m, so as to meet your various demands;

- When the heavy-duty equipment is applied, heat setting process will be utilized to reduce the risks of deformation and corrugation;

- Excellent properties of acid and alkali resistance, abrasion and corrosion resistance, longer service life are available to you;

- With working temperature ranging from -20°C to 200°C;

- Easy for cleaning;

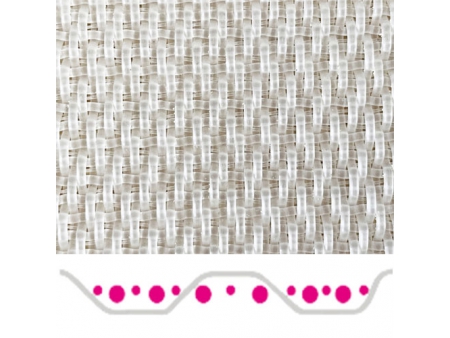

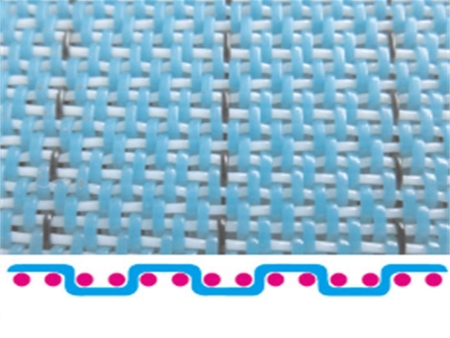

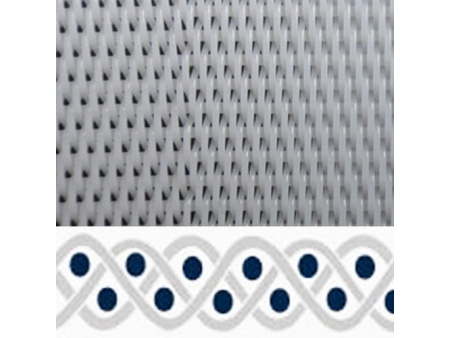

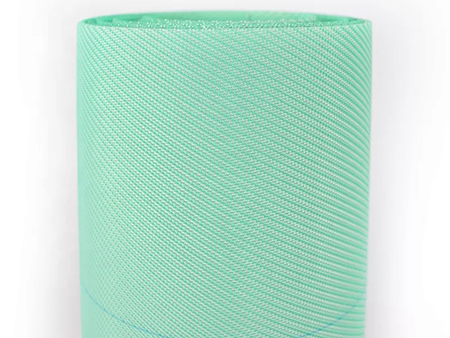

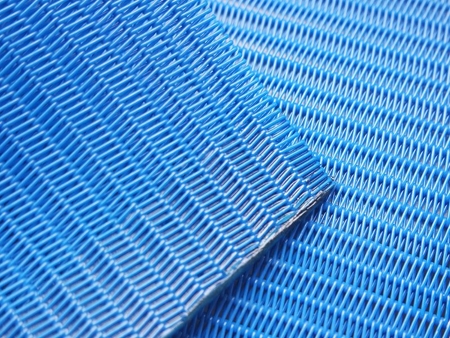

The spirally structured press filter mesh is specially designed to achieve paper pulp washing and drying for paper machine clothing. Furthermore, this kind of polyester belt is capable of reducing material loss from the mesh opening, which is applicable in sludge desiccation, paper pulp washing, coal washing, pharmaceutical, chemical, alcohol, vinegar industries, etc.

Specifications| Model | Thread diameter (mm) | Thickness (mm) | Weight (kg/m²) | Air permeability (m³/m²h) | ||

| Warp | Weft | Filling yarn | ||||

| Large loop | 0.9 | 1.1 | 1.0×4 | 3 | 1.9 | 5250 ±500 |

| Middle loop | 0.7 | 0.9 | 0.8×3 | 2.5 | 1.7 | 4750 ±500 |

| Small loop | 0.5 | 0.7 | 0.6×3 | 1.9 | 1.4 | 4000 ±500 |

- The polyester spiral press filter mesh is featured with good stability and long service life;

- The width of the filter mesh ranges from 20 to 500 cm, which depends on the specifications of the filtering equipment;

- The edge of this spiral filter mesh is covered with rubber, so as to enhance its abrasion resistance and structural stability;

- No seams at the joints of the filter mesh;