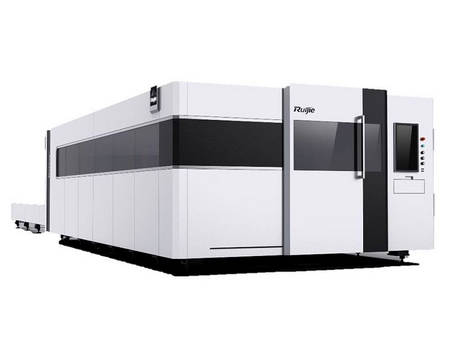

High Power Fiber Laser Cutting Machine, RJ-G6025

Laser metal cutter for medium-thick sheet metal cutting

RJ-G6025 fiber laser cutting machine is designed with high power of 4000-20000W, suitable for cutting metal plates of 100mm in thickness. This fiber laser cutter is a high cost-effective solution for processing medium-thick sheet metals.

- Laser power

- 3000-20000W (optional)

- Max. acceleration

- 1.5G

- Repositioning accuracy

- ±0.02mm

- Power supply

- AC 380V, 3-phase, 50/60Hz

- Max. cutting speed

- 110m/min

- Cutting area

- 2500×6000mm

optional:

1530×4050mm

2030×4050mm

2030×6050mm

2530×6050mm

2530×8050mm

-

Full Enclosure Design

The full enclosure design coupled with efficient zoned fume extraction system ensures safe operation and environmental protection. The exchange platform helps improve the working efficiency.

-

Heavy Duty Welded Bed

The machine bed is constructed with high-strength carbon structural steel by welding. The welded bed has undergone a 600°C heat treatment, efficiently ensuring high durability of structure and enabling it able to last for 20 years without deformation.

-

Fourth Generation of Aviation Aluminum Crossbeam

The crossbeam is made from aviation aluminum alloy that has good dynamic performance. The beam is designed with honeycomb structure to provide better structural strength.

-

Auto Focus Laser Cutting Head

Precitec laser cutting head is utilized for fast cutting with high stability.

-

IPG Laser Source

The fiber laser cutter adopts advanced laser source from world-class brand IPG or nLight that is internationally recognized expert for highly reflective material cutting.

-

Independent Control Cabinet

The control cabinet features a design of dustproof and vibration resistance, efficiently prolonging the service life of electrical components.

-

IPAD Screen Design

Tempered glass panel design provides high definition effect and smooth operation.

-

Newly Developed Laser Head Protective Cover

The laser head is guarded by protective cover which allows for clear observing of red light, good heat dissipation and minimal dust, efficiently avoiding cause the gas path inside the cutting head to burn.