Online Flying Fiber Laser Marking Machine

- Laser wavelength 1064nm

- Marking range 110×110mm

- Beam quality M²<1.5

- Max. line speed 12000mm/s

Designed specifically for high-speed production lines, the online flying fiber laser marking machine integrates an industrial-grade fiber laser and a high-speed galvo scanner system. It supports synchronous marking on production lines moving at 0-30m/min, allowing for permanent product identification without stopping the line. With scanning speeds up to 12,000mm/s, it boosts daily production capacity by 200%. It seamlessly integrates with PLC systems, enabling fully automatic serial number, QR code, and batch number generation and traceability. Requiring zero consumables and causing no ink pollution, it complies with FDA/CE certifications, meeting safety standards for food packaging and medical-grade applications.

- Metals: Iron, steel, carbon steel, stainless steel, pure aluminum, aluminum alloy, zinc alloy, titanium alloy, brass, bronze, gold, silver, platinum

- Plastics: ABS, PVC, PE, HDPE

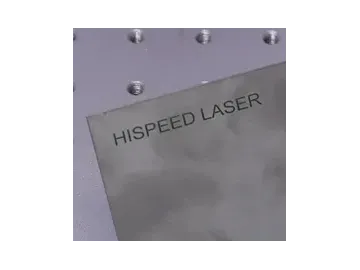

- Aluminum alloy laser marking

- PVC pipe laser marking

- Paper box laser marking

- Aluminum bottle cap laser marking

- Aluminum can bottom laser marking

- Aluminum bottle cap laser marking

- Aluminum can top laser marking

- Technical Data

- Configuration

- Laser power 30W, 50W, 100W

- Laser type fiber laser

- Laser wavelength 1064nm

- Marking range 110×110mm

- Beam quality M²<1.5

- Max. line speed 12000mm/s

- Min. character size 0.05mm

- Min. line width 0.01mm

- Cooling method air cooling

- Power supply 220V/50Hz or 110V/60Hz

- Operating temperature 5℃~40℃ (operation outside this range may affect performance and lifespan)

- Machine dimensions 480×660×1450mm

- Package size 1330×580×560mm

- Machine weight 66kg

- Package weight 76kg

Laser source

We provide Raycus, JPT, MAX, SUPER, and IPG laser sources for our laser equipment, featuring high pump conversion efficiency, low power consumption, and excellent beam quality.

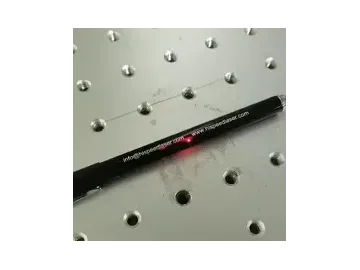

Galvo scanner

A 12000mm/s high-speed scanning head, primarily used for laser marking. It is equipped with a dual-red-light focusing device, which significantly enhances focusing efficiency.

F-theta lens

Equipped with an F-theta lens for 1064nm wavelength, mainly used in fiber laser marking machines. Due to its longer wavelength, it offers strong energy penetration, making it suitable for marking various metal and non-metal materials. It supports long-term operation without the need for consumables to be added or replaced. Currently, we have received no user feedback regarding F-theta lens damage.

Control card

Equipped with a genuine JCZ EZCAD control board, ensuring the stability of the entire marking system. The software interface supports multiple language versions (Chinese, English, Italian, Russian, Korean, Japanese, Spanish, Portuguese, etc.). Its powerful functions include text marking, QR code marking, vector graphic marking, automatic serial number skipping, and more.

Touchscreen display

Features a 10.1-inch industrial-grade capacitive touchscreen, supporting multi-touch for 'What You See Is What You Get' intuitive operation with icon- and color-block distinguished function modules. It boasts high-speed data processing and communication capabilities, with multi-protocol interface compatibility, integrating Ethernet, RS232, and other interfaces for real-time production data upload and remote command reception.

Laser safety warning labels

Play a crucial role in scenarios involving laser applications, primarily serving to alert people to potential laser hazards and ensure personnel safety.

- Fume Extractor

- Conveyor line

- Fiber laser

- High-speed galvo scanner

- 1200mm z-axis 500mm y-axis (gantry/column for integration)

- Laser control cabinet

- F-theta lens

- Control card

- Touchscreen display

- Encoder

- Sensor

- Laser power supply

- Power cord

- Safety goggles

- Foot pedal switch

- Aluminum test piece

- Hex key tool set

- Equipment warranty certificate

- Shipping accessories list

- Product catalog