Split Fiber Laser Marking Machine

- Laser wavelength 1064nm

- Marking range 50×50mm~300×300mm

- Beam quality M²<1.5

- Max. line speed 7000mm/s

The split fiber laser marking machine features a modular design as its core advantage. The separated layout of the laser control cabinet and the workstation significantly enhances equipment flexibility and heat dissipation efficiency, making it particularly suitable for factories that require frequent adjustments to production line configurations. Users can freely expand or move equipment components based on production needs, without being constrained by fixed workstations, while also reducing reliance on extensive workshop space. Whether for engraving metal components, micro-marking electronic parts, or high-precision medical device identification, this machine delivers stable and efficient output, meeting the rigorous industrial demands of multi-scenario and multi-material applications.

- Metals: Iron, steel, carbon steel, stainless steel, pure aluminum, aluminum alloy, zinc alloy, titanium alloy, brass, bronze, gold, silver, platinum

- Plastics: ABS, PVC, PE, HDPE

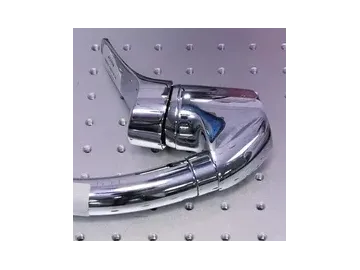

- Stainless steel faucet laser marking

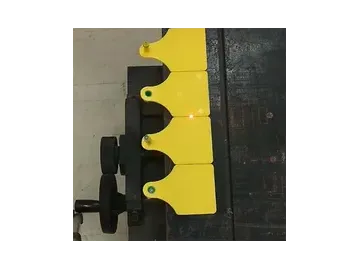

- Animal ear tag laser marking

- Metal pendant laser marking

- Business card case laser marking

- Artwork laser engraving

- Brass laser marking

- Metal sign laser engraving

- Aluminum oxide laser marking

- Stainless steel necklace laser marking

- Plastic shell laser marking

- Metal jewelry laser marking

- Copper block laser marking

- Metal ring laser marking

- PU leather laser marking

- Technical Data

- Configuration

- Laser power 20W, 30W, 50W, 60W, 100W, 120W, 200W

- Laser type fiber laser

- Laser wavelength 1064nm

- Marking range 50×50mm~300×300mm

- Beam quality M²<1.5

- Max. line speed 7000mm/s

- Min. character size 0.05mm

- Min. line width 0.01mm

- Cooling method air cooling

- Power supply 110V~240V, 50~60Hz

- Operating temperature 5℃~40℃ (operation outside this range may affect performance and lifespan)

- Machine dimensions 320×550×700mm, 210×450×400mm

- Package size 800×450×770mm

- Machine weight 47kg

- Package weight 57kg

Laser source

We provide Raycus, JPT, MAX, SUPER, and IPG laser sources for our laser equipment, featuring high pump conversion efficiency, low power consumption, and excellent beam quality.

Galvo scanner

The 7110 model galvo scanner is characterized by high-speed scanning of 7000mm/s, primarily used for laser marking and engraving. It is equipped with a dual-red-light focusing device, which significantly enhances focusing efficiency.

F-theta lens

Equipped with an F-theta lens for 1064nm wavelength, mainly used in fiber laser marking machines. Due to its longer wavelength, it offers strong energy penetration, making it suitable for marking various metal and non-metal materials. It supports long-term operation without the need for consumables to be added or replaced. Currently, we have received no user feedback regarding F-theta lens damage.

Control card

Equipped with a genuine JCZ EZCAD control board, ensuring the stability of the entire marking system. The software interface supports multiple language versions (Chinese, English, Italian, Russian, Korean, Japanese, Spanish, Portuguese, etc.). Its powerful functions include text marking, QR code marking, vector graphic marking, automatic serial number skipping, and more.

Laptop

Features a major brand Lenovo laptop, equipped with a Windows 10 system and a 14-inch display, to ensure smoother operation of the entire laser equipment.

Column

Made of aluminum alloy, with clear scale markings for smooth movement, adapting to marking for workpieces of different heights.

Laser safety warning labels

Play a crucial role in scenarios involving laser applications, primarily serving to alert people to potential laser hazards and ensure personnel safety.

- Fume Extractor

- Cutting fixture (laser engraving vise)

- F-theta lens

- Rotary axis for ring

- Rotary roller

- Rotary axis

- Fiber laser

- Portable laser control cabinet

- Work panel

- Galvo scanner

- F-theta lens

- Control card

- Laser power supply

- Laptop

- Power cord

- Safety goggles

- Foot pedal switch

- Aluminum test piece

- Hex key tool set

- Equipment warranty certificate

- Shipping accessories list

- Product catalog