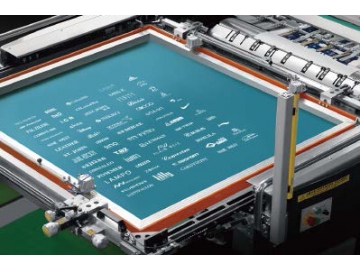

Automatic Servo Control Screen Printing Press

JB-106A

The JB-106A automatic servo control screen printing press is an independently developed product introduced by JINBAO. The printing press is a newly designed intelligent screen printing press. The machine includes three patented features and five utility models. It operates with extremely high printing quality and efficiency.

The speed can reach up to 5000 pieces/hr. For some custom products, the printing speed can surpass 6000 pieces/hr. These screen printing presses are the best choice for industries applying print to paper or plastic fine packages, ceramics, decal paper, metal signs, plastic membrane switches, and electronic parts.

| Model | |

| Max. sheet size | 1060×750mm2 |

| Min. sheet size | 560×350mm2 |

| Max. Printing size | 1050×750mm2 |

| Frame size | 1300×1170mm2 |

| Substrate thickness | 90-420g/m2 |

| Printing speed | 800-5000pcs/h |

| Power required | 3P 380V 50Hz 24kw |

| Total weight | 4600kg |

| Overall size | 4070×3350×2050mm |

- Detachable screen printing plate

The frame of the screen printing plate can be disassembled from the transmission parts and pulled out to realize convenient printing target registration and material feeding adjustment. This also makes cleaning the roller and plate safer and much easier. The automatic electric eye detection system ensures the reliability of disassembly of the plates, preventing breakage of the rack and damage to the main drive.

- Ultra-precise pneumatic scraper system

Our JB-106A automatic servo control screen printing press features a high-precision scraper system of which the descending pressure of the scraper can be pre-set. The position is also controlled while the pressure of the rubber scraper remains constant after calibration, maintaining a constant thickness of the ink layer. This results in perfect and uniform presswork.

- Screen printing plate compensation device

This device can realize automatic compensation of the printing plate length by contraction and extension. The compensation is targeting the paper length changing before and after the previous printing process.

- Printing bench

The three-dimensional electric screen printing plate micro-adjusting system enables remote, three-dimensional and electric screen printing plate adjustment by entering the stroke to be adjusted. The adjustment can be realized in one step so the machine is convenient and practical in operation.

- Nylon rack

The synchronous movement of the screen printing plate and roller is driven by a durable nylon rack and steel gear. The gear guarantees that there will be no motion error or retrace error between gears and racks as the components are precision machined. Therefore, there will be low abrasion, extending the service life of the machine.

- Pneumatic side guide

The pneumatic side guide prevents improper printing due to a lack of ink and protects the prints from being polluted. The positioning of the pulling and pushing of the side guide is highly precise. The stroke of the positioning is long, and the speed is quick for convenient adjustment. The photoelectrical detecting system monitors the position of the printing target in real time, reducing the ration of wasted printing products.