Automatic Screen Printing Press, DBSY-350

Request a Quote

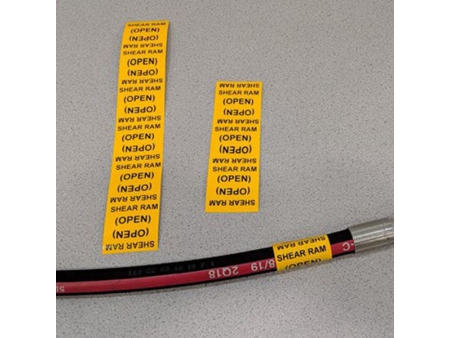

Roll to roll label printing machine

Introducing our automatic screen printing press, capable of reaching a maximum speed of 9,000 revs per hour with printing precision of ±0.20mm. This printing machine features top-quality components from Japan, ensuring efficient and stable printing while maintaining high accuracy. The touchscreen control panel makes production operations easy and convenient.

Applicable Materials

- PET, PVC, PC, BOPP, and other rolled materials.

- Widely used in label printing, adhesive paper printing, membrane switch, IMD, film varnishing and coating, and more.

Specifications

| Model | DBSY-350 |

| Maximum Substrate Width | 350mm |

| Maximum Printing Size | 350*400mm |

| Maximum Printing Speed | 1000~9000RPH |

| Frame Size | 550*700mm |

| Accuracy | ±0.20mm |

| UV Curer Power | 7.2KW |

| Maximum Unwinding Diameter | 700mm |

| Maximum Rewinding Diameter | 700mm |

| Dimensions (L*W*H) | 4650* 1100 * 1670mm |

| Weight | 2500KG |

Features

- Applicable for printing scratch-off cards and cosmetic labels, as well as overprinting and varnishing labels

- Equipped with Yaskawa servo motors from Japan for precision and stability

- User-friendly touch screen control panel for easy operation.

- Adjustable angles and pressure of the doctor blade and inkjet bar to accommodate different printing tasks.

- Sturdy aluminum alloy frame ensures high stability, eliminating the risk of deformation.

- Pneumatic shafts for unwinding and rewinding, making film loading and unloading convenient.

- Material feeding system driven by servo motors to ensure consistent feeding according to set parameters.

- Advanced ultrasonic sensors in the rewinder monitor the transparency of the printed films.

- Precision linear guides in the horizontal slide rail ensure smooth and stable printing.

- Equipped with two sets of UV lamps for efficient and fast ink curing.

Details

- Unwinding Unit

- 3-inch air-expanding shaft equipped for loading substrate rolls

- Automatic rewinding sensor detects substrate shortage; if positive, the machine will be shut down automatically.

- Printing Unit

- Equipped with Panasonic high-precision photoelectric sensors in three colors

- Equipped with high-quality aluminum alloy screen frames

- Drying unit

- Two 3.8-kW UV lights equipped for efficient ink curing

- Traction Unit

- Material feeding traction controlled by Yaskawa servo motors from Japan

- Rewinding Unit

- 3-inch air-expanding shaft equipped for rewinding substrate rolls

- Equipped with material collecting sensor