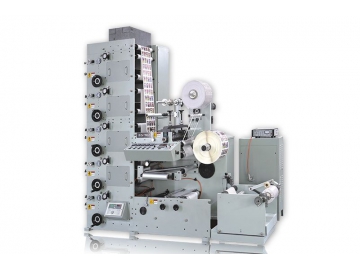

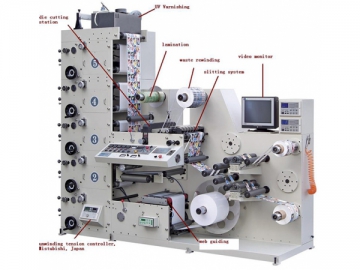

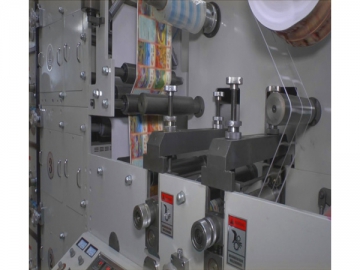

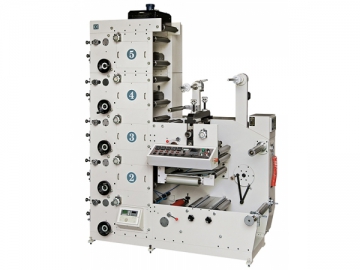

Flexographic Printing Press (RY320 Label and Paper Printing Machine)

With a maximum web width of 320mm, the RY320 series flexographic printing press doesn't take up a lot of floor space, but it accurately matches color and is affordable for small-scale operations. Our label and paper printing machine prints narrow labels on paper, film, and self-adhesive tags for use in supermarkets, drug stores and department stores.

Characteristic:

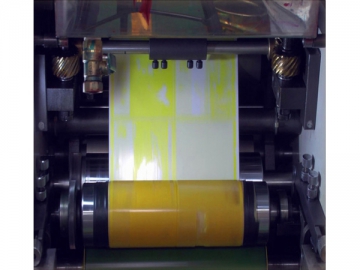

1. Our flexographic printing press uses the ceramic anilox roller to transfer the ink.

2. The unwinding and rewinding is controlled by the magnetic powder controller and the clutch (or Mitsubishi auto tension controller as optional).

3. Each printing unit of the printing equipment adopts the regulation of 360ºcircumferential direction.

4. Each printing unit has a set of UV dryer.

5. When the printing machine stops working, the inking roller can automatically fall off and work at a low speed, to keep the ink from drying.

6. The main motor of the flexographic printing press uses the imported variable frequency stepless speed controller.

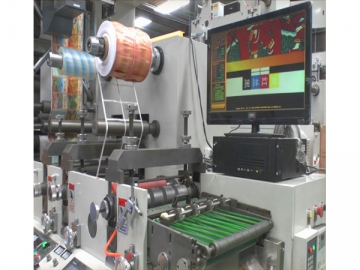

7.This printing machine can get all the processes done at one time, from the paper feeding, printing, varnishing, automatic UV drying, laminating and rolling. It is ideally suited for the printing plant to print the commercial bills and high-grade adhesive.

RY320B

Standard Configuration

1. A simple plate mounting machine

2. An anilox roller for each printing station

3. Three printing rollers for each printing station (according to customer requirements)

4. Turn bar: for printing on both sides at the same time

5. Lamination station

6. Unwinding tension controller (Mitsubishi, Japan)

7. Rewinding tension controller

8. A rotary die-cutting station

| Model | RY320B |

| Printing speed | 60m/min |

| Printing color | 1-10 colors |

| Max. web width | 320mm |

| Max. printing width | 310mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 550mm |

| Printing girth | 175-380mm |

| Precision of registration | ±0.10mm |

| External dimension | 2800*1400*3200(mm) |

| Total weight | About 2800kg |

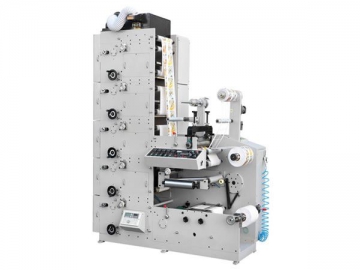

RY320C

Standard configuration

1. A simple plate mounting machine

2. An anilox roller for each printing station

3. Three printing rollers for each printing station (according to customer requirements)

4. Turn bar: for printing on both sides at the same time

5. Lamination station

6. Unwinding tension controller (Mitsubishi, Japan)

7. Rewinding tension controller

8. A rotary die-cutting station

9. A slitting station

| Model | RY320C |

| Printing speed | 60m /min |

| Printing color | 1-10 colors |

| Max. web width | 320mm |

| Max. printing width | 310mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 550mm |

| Printing girth | 175-380mm |

| Precision of registration | ±0.10mm |

| External dimension | 2800*1400*3200(mm) |

| Total weight | About 2800kg |

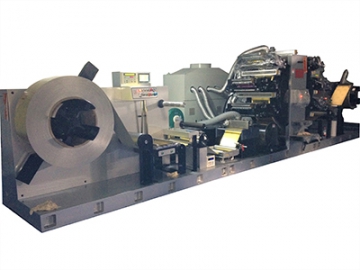

RY320D

Standard configuration

1. A simple plate mounting machine

2. An anilox roller for each printing station

3. Three printing rollers for each printing station (according to customer requirements)

4. Turn bar: for printing on both sides at the same time

5. Lamination station

6. Unwinding tension controller (Mitsubishi, Japan)

7. Rewinding tension controller

8. A rotary die-cutting station

9. A slitting station and a paper receiving table

| Model | RY320D |

| Printing speed | 60m/min |

| Printing color | 1-10 colors |

| Max. web width | 320mm |

| Max. printing width | 310mm |

| Max. unwinding diameter | 600mm |

| Max. rewinding diameter | 550mm |

| Printing girth | 175-380mm |

| Precision of registration | ±0.10mm |

| External dimension | 2800*1400*3200(mm) |

| Total weight | About 2800kg |

Our company stands out through the combination of professionalism and technical expertise in the field of printing, designing, manufacturing and maintenance. Our facilities are equipped with all machinery needed to get the job done to the highest standard. We have optimized our production management system in order to adapt our printing equipment to the different needs of the label printing industry. Our substantial base of experience has allowed us to come up with the most complete catalog of printing machinery, including flexographic printing presses, intermittent rotary printing presses, roll-to-roll continuous screen printing presses, adhesive labels die-cutting machines, automatic slitting machines, label inspection machines, composite machines and auxiliary equipment. Our commitment to innovation resulted in the development of the automatic chromatography high-speed flexographic printing press, the PS printing press and high-capacity and low-power equipment. These printing machines find multiple applications in a number of industries, such as clothing labels, tag cards, medicine, food, daily chemicals, electronics, toys, gifts, stationery, barcode labels, and many others. Our products enjoy a great reputation in Europe, America and Southeast Asia, and we have established long-term partnerships with foreign distributors.

Important Order Information

Lead time: 60 days

Terms of payment: 30% of deposit after signing the contract, 70% of balance payment to be paid before delivery.

Installation and commissioning: When the machine reaches the buyer’s plant, our technical personnel will carry out the installation and its commissioning. We will also provide a basic training in how to operate the machine.

Guarantee period: One year. During the guarantee period, we will replace any parts damaged due to quality problems with no additional costs. Shipping not included. Failure due to improper use of the machine voids the guarantee.

Related Names

Label Printing Machine | Paper Label Flexo Printing Machine | Label Flexo Printing Machine | Narrow Label Print Machine

.jpg)