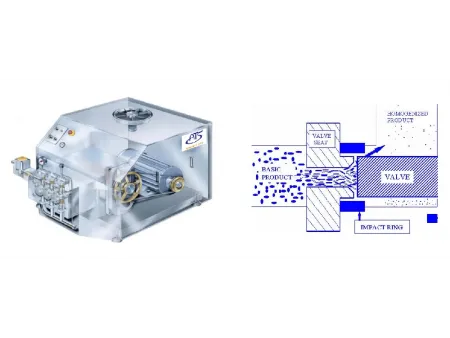

Laboratory Homogenizer

ATS laboratory-type high-pressure homogenizer is designed for laboratory-scale processing of nanoparticles, nanodispersions, nanoemulsions, and cell disruption in R&D and small-batch production. This homogenizer can also be used in small batch processing of milk, dairy products, juices, beverages, and other liquid foods. Four models are available to provide precise solutions for different application scales and R&D requirements.

| Models | ||||

|---|---|---|---|---|

| Flow Rate (L/H) | 5-10 | 5-15 | 10 | 20-30 |

| Min. Volume (ml) | 10 | 25 | 25 | 40 |

| Working Pressure (bar) | 0-1800 | 0-1500 | 0-1500 | 0-1000 |

| Power (kW) | 1.5 | 1.5 | 1.5 | 2.2 |

| Dimensions (mm) | 450*720*475 | 450*720*475 | 450*720*475 | 840*525*480 |

| Weight (kg) | 128 | 130 | 130 | 168 |

| Key Features | Laboratory high-pressure nano homogenizer engineered for R&D applications in small-volume,high-viscosity,and high-value samples. | Specialized homogenizer for cell disruption and nanoemulsion homogenization. Efficient cooling performance provides a clear advantage in the biological cell disruption process. | Versatile laboratory homogenizer,especially suited for costly pharmaceutical raw materials and excipients. | Larger-capacity benchtop homogenizer designed for laboratory settings. |

- Purpose-built for small-batch sample processing with zero material residue, ideal for laboratories or small R&D environments

- Direct sample feeding without venting

- Built-in temperature-control module ensures sample stability during processing

- Intuitive and user-friendly 7-inch high-resolution touchscreen with visual pressure trends graph and alarms

- Wetted parts made of 316L or higher-grade stainless steel, offering high corrosion and heat resistance, ensuring high-performance and stability for long-term use

- Multiple over-pressure protections to ensure reliability and safe operations

- CE certified and GMP compliant, while supporting CIP/SIP cleaning

The homogenizers use a motor-powered high-pressure plunger pump. The pump pressurizes the sample and forces it through a narrow homogenizing valve, where a sharp pressure drop (up to 2000 bar) generates intense shear, turbulence, and cavitation to achieve homogenization, dispersion, and disruption.

- Cell disruption of Pichia pastoris yeast

- Collagen homogenization

- Cell disruption of E. coli bacteria

- Nanoemulsion preparation

- Slurry blending dispersion of carbon nanotubes (CNTs).

Let us help you find the right nano-processing equipment to support your R&D, scale-up, and production needs.