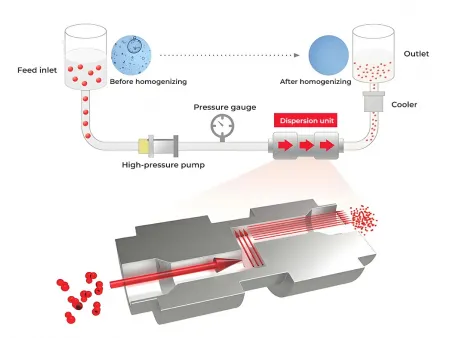

Laboratory Micro-Jet Homogenizer (Microfluidic Homogenizer)

This micro-jet homogenizer is a laboratory-scale high-shear fluid processor designed for nanoscale homogenization processes requiring stringent particle-size control.

| Models | ||

|---|---|---|

| Min. Volume (ml) | 15 | 20 |

| Flow Rate (L/H) | 3-5 | 5-8 |

| Working Pressure (bar) | 0-2500 | 0-2070 |

| Power (kW) | 2.5 | 2.5 |

| Chamber Configuration | Main 75Y/Z63 auxiliary Z300 (optional) | Main 75Y/Z75 auxiliary Z300 (optional) |

| Dimension (mm) | 709*419*345 | 945*445*345 |

| Weight (kg) | 50 | 60 |

- This micro-jet homogenizer is a new generation of high-pressure homogenizer, using unique diamond microchannel ultra-high-speed jet technology to achieve smaller and more uniform nano-scale particle sizes homogenization compared with ordinary high-pressure homogenizers. This micro-jet homogenizer is ideal for high-value applications requiring uniform nano-scale particle sizes across various industries.

- Utilizing Diamond Interaction Chamber (DIXC) as the core component of the micro-jet homogenizer. Unlike regular high-pressure homogenizers with adjustable gap valves, the microchannels within DIXC are of fixed size and cannot be altered. Consequently, the micro-jet homogenizer can maintain consistent homogenization conditions, facilitating the production of uniform-sized nanoparticles that ensure highly stable results across batches under consistent process parameters.

- Linear scale-up production involves arranging multiple identical microchannels in parallel within the diamond interaction chamber of a micro-jet homogenizer. By using multiple microchannels with the same performance as those in lab-scale homogenizers and employing a high-power intensifier pump, the R&D process can be scaled linearly. This allows industrial-scale homogenizers to increase output without changing the homogenization quality, a feat difficult for standard high-pressure homogenizers. As a result, many high-requirement scenarios choose micro-jet homogenizers to avoid scale-up production problems after successful, costly labo-scale testing.

- The micro-jet homogenizer uses hydraulic pressure intensification to generate homogenization power. Its hydraulic power unit can produce very high homogenization pressures (hundreds of MPa) while operating at relatively low hydraulic pressures (a minimum of dozens of MPa). Under these conditions, the hydraulic power unit can run continuously and stably while still providing very high homogenization pressure. Compared to the complex high-frequency ultrasonic homogenizer with a connecting rod design used in ordinary high-pressure homogenizers, the hydraulic intensification system greatly reduces the equipment's failure rate, ensuring smooth and uninterrupted production.

The fluid sample is rapidly forced through the narrow gaps within the dispersion unit under high pressure. The sudden pressure drops generate extremely high-speed velocities, leading to intense turbulence, cavitation, shear forces, and jet flow, which break apart the particles, reducing them into a fine and uniform nano-scale homogeneous state. Furthermore, the hydraulic intensifier power mode can provide a stable pressure of up to 200 MPa.

Turbulence

Turbulence is caused by the mutual collisions of sample molecules due to cavitation.

Shearing

Shearing in fluids occurs due to the friction between the molecules and the wall of the dispersion unit, viscosity, etc.

Cavitation

Cavitation refers to the cavities or bubbles created in fluids. If the velocity increases, the cohesive force between molecules and the voids or bubbles in the liquid rapidly collapses, generating a shock wave.